MAX200

MAX300/400

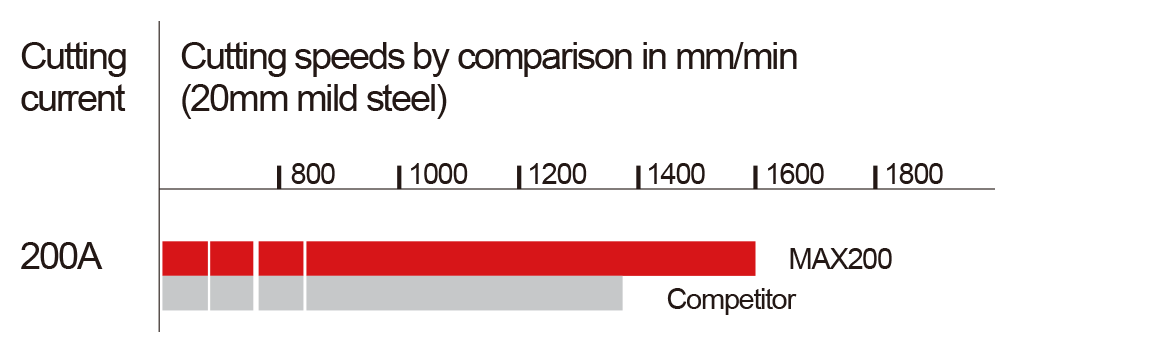

Maximized Productivity

Long-life Consumables

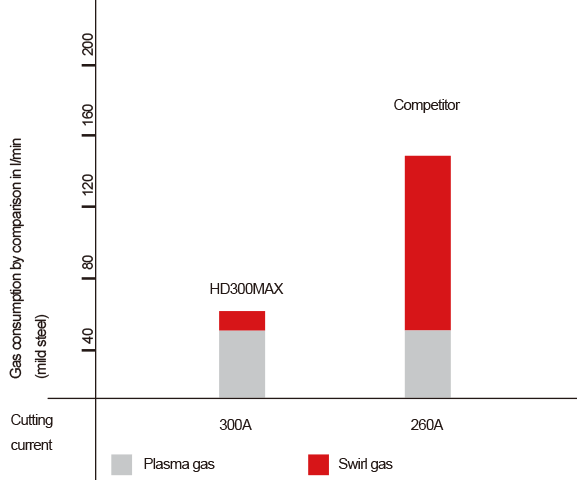

Efficient Gas Supply

Superior Cutting Performance

Cutting Capacity

| MAX200 | MAX300 | MAX400 | |

|---|---|---|---|

| Mild steel cut capacity | Thickness | Thickness | Thickness | Dross free* | 25mm | 35mm | 40mm |

| Production pierce | 30mm | 40mm | 50mm |

| Maximum cutting capacity | 50mm | 70mm | 80mm |

* Feature and material type can influence dross free performance.

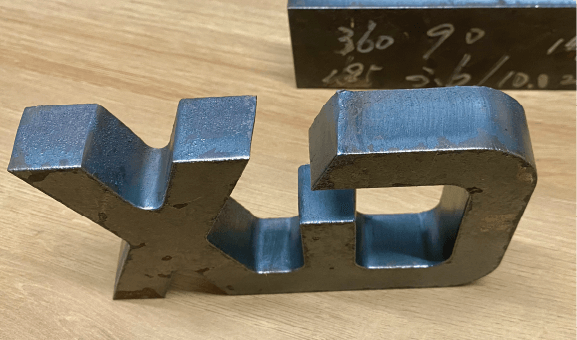

Typical Cutting Sample

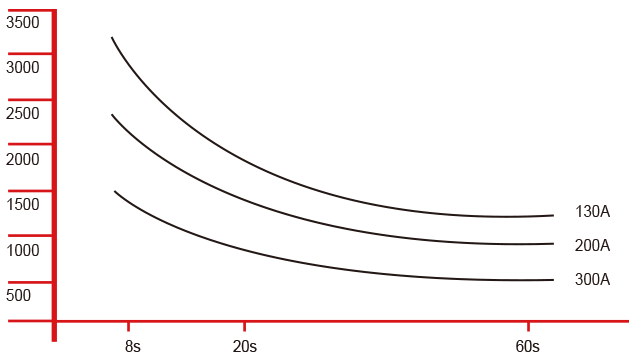

Operating Data (Mild Steel)

| MAX200 | MAX300 | MAX400 | ||||

|---|---|---|---|---|---|---|

| Material thickness (mm) |

Cutting speed (mm/min) | Cutting current (A) | Cutting speed (mm/min) | Cutting current (A) | Cutting speed (mm/min) | Cutting current (A) |

| 10 | 200 | 3500 | - | - | - | - |

| 16 | 200 | 2300 | 300 | 3100 | - | - |

| 20 | 200 | 1600 | 300 | 2100 | 400 | 2800 |

| 25 | 200 | 1200 | 300 | 1600 | 400 | 2200 |

| 30 | 200 | 800 | 300 | 1200 | 400 | 1800 |

| 40 | - | - | 300 | 850 | 400 | 1150 |

| 50 | - | - | 300 | 400 | 400 | 700 |

| 60 | - | - | - | - | 400 | 550 |

| 70 | - | - | - | - | 400 | 350 |

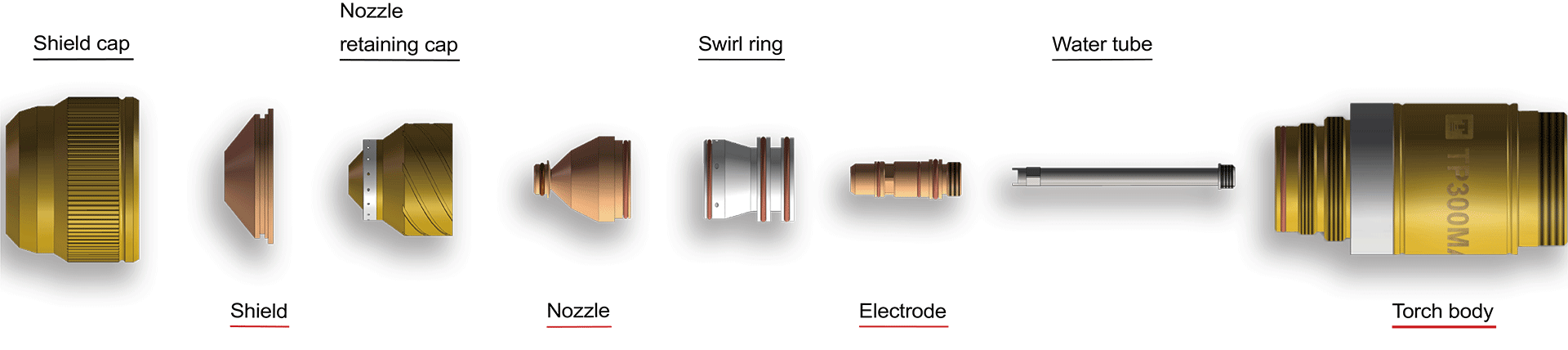

Long-life Consumables’ Technology

Torch Improvement

Optimized gas parameters are set and controlled by the software. With air or oxygen plasma gas, the MAX300 plasma cutting system achieves impressive cut speeds, consistent cut quality and exceptional consumable life.

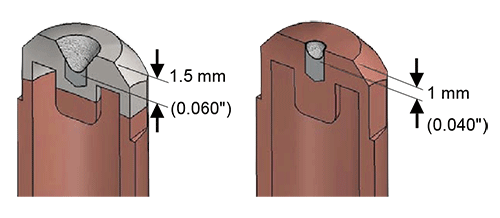

TP300MAX electrodes get Structure promotion,which utilize a hafnium/silver interface at the point of electrical transfer. The hafnium/silver interface extracts more heat and has a stronger bond, enabling a deeper pit depth in the hafnium.

TP300MAX electrodes burn almost twice as deep as standard copper electrodes,doubling SilverPlus life over a standard copper electrode dramatically longer electrode and nozzle lifeincreasing productivity and lowering operating costs.

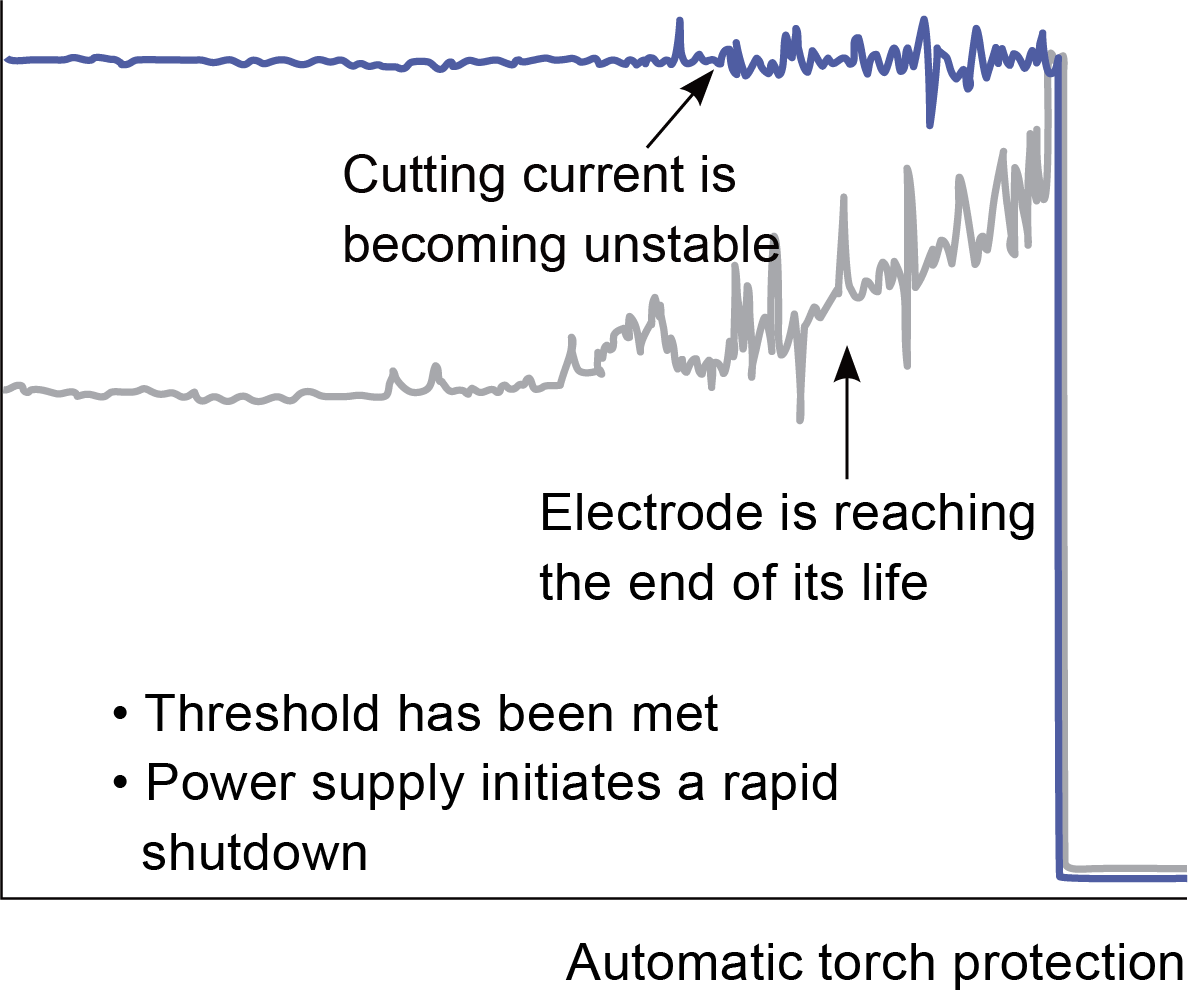

Automatic torch protection

The updated module response and disconnected in time after sensing the unstable current due to the electrode's wear and tear,which dramatically protect torch and extend consumable life.

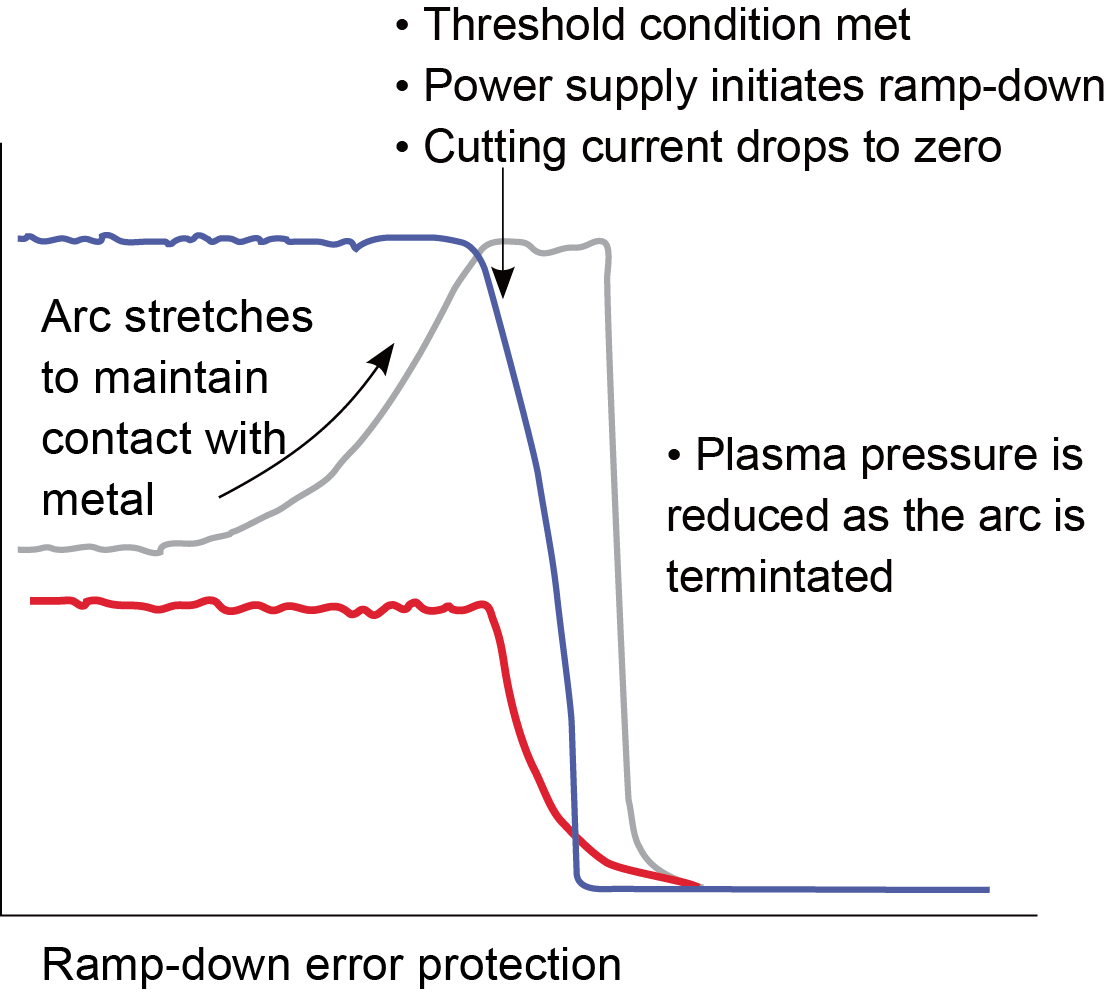

Automatic ramp-down error protection

when cutting end without proper ramp down of current and gas flow,the module senses and response in time Power supply initiates ramp-down and cutting current drops to zero to protect electorde,effectively exending consumables life.

BEVEL cutting

CNC cutting

LET'S STAY IN TOUCH

Get updates on sales specials and more

FOLLOW US

We want to hear from you!

Copyright © 2022 HANGZHOU TOPWELL TECHNOLOGY CO.,LTD. | 浙ICP备2022006748号