PROMIG 200SYN Pulse

Versatile and synergy tool for the portable welder

Application:

Metal Fabrication

Maintenance and Repair

Auto Body,

Light Industrial

Processes:

MIG

Flux-Cored

TIG(Lift TIG)

MMA(Stick)

Input Power:

230V, 1-Phase

Amperage Range: 10-200A

Rated Output at 40℃ (104℉):

200A at 24V @60% Duty Cycle

Weight:20KG

Advanced Features:

-

Multi-Process Capable - Welds flux-cored, stick, TIG, Pulse MIG, advanced MIG for M.S/S.S.

-

Pulse MIG Process - Welds 4XXX and 5XXX series aluminum for superior quality welding.

-

Synergic Control - Set weld procedures with one control.

-

Built-in featured waveform - Provides a smooth, stable arc and superior, repeatable welds.

-

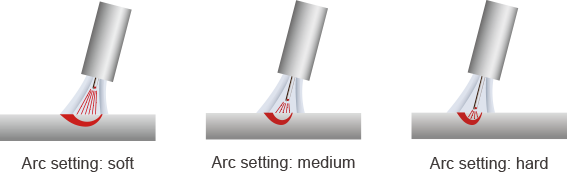

Dynamic Control - controls the welding arc cone width from a softer arc to a harder arc.

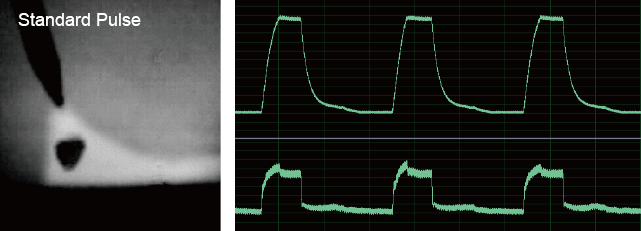

Pulse MIG

The Pulse MIG process works by forming one droplet of molten metal at the end of the electrode per pulse. Then, just the right amount of current is added to push that one droplet across the arc and into the puddle. The transfer of these droplets occurs through the arc, one droplet per pulse.

With the advanced Pulse MIG, you can easily get a cosmetically pleasing weld seam, with significantly lower and more controller heat input into the workpiece. It results in much lower distortion and less rework, very suitable for welding the thin Aluminum sheets.

MULTI-PROCESS

Many machines claim they are multi-process, but are little more than a MIG machine in disguise. ProMIG-200SYN Pulse is a true multi-process welder, which means whether you are welding MIG/MAG with solid or Flux-Cored wire, MMA – even the most tricky electrodes – or Lift TIG, ProMIG-200SYN Pulse will perform like it was born to run that process.

Dynamic control

Dynamic control allows the welder, for the first time, to variably adjust a pulse welding machine to a wide range of jobs and welding positions as well as to his personal preferences. The welder can use a controller to directly access the arc characteristic and change it from soft to hard.

Simple Operation

3 Steps to achieve weld perfection

1. Select operation mode

2. Select Job-list No.

3. Adjust welding current

(always the perfect setting by the synergic function using the material thickness)

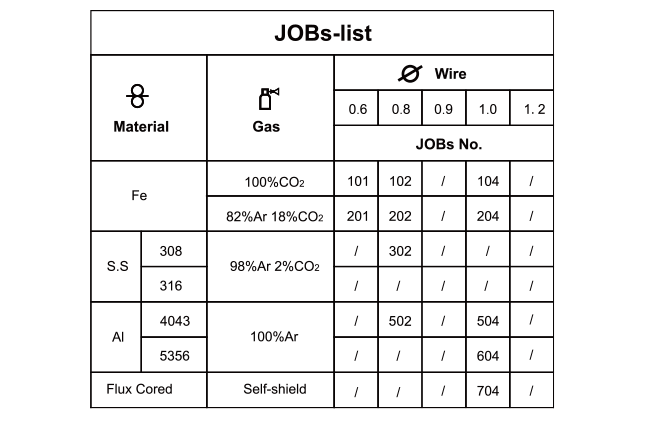

Synergy control with job-list

The Job-lists display is easily and intuitively controlled through its graphical user interface.We assembled the perfect welding curve in every Job-No. for highly efficient multi-process welding of carbon steels and stainless steel and aluminum alloys. Operation is easier than ever before.

LET'S STAY IN TOUCH

Get updates on sales specials and more

FOLLOW US

We want to hear from you!

Copyright © 2022 HANGZHOU TOPWELL TECHNOLOGY CO.,LTD. | 浙ICP备2022006748号