Industrial Applications:

Boat, ship and yacht building

General manufacturing

General fabrication

Structural steel fabrication

Transportation

Sheet metal fabrication

Light-gauge tube and sheet

Machines Processes:

Stick (SMAW)

Flux-Cored (FCAW)

MIG (GMAW)

Pulsed MIG (GMAW-P)

High-Speed Double Pulse (GMAW-HDP)

High Speed Pulsed MIG (GMAW-HSP)

Input Voltage:

3PH ~ 400V ±15%

Output Range:

30A ~ 500A

Rated Output(40℃) 60%:

500A/39V

Net Weight:

81.5kg

Wire Feeder:

4-Rollers

Advanced Features

Simple Operation

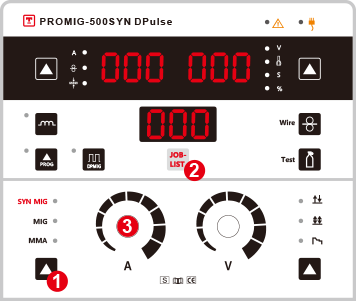

3 Steps to achieve weld perfection

1. Select operation mode.

2. Select Job-list No.

3. Adjust welding current.

Always the perfect setting by the synergic function using the material thickness.

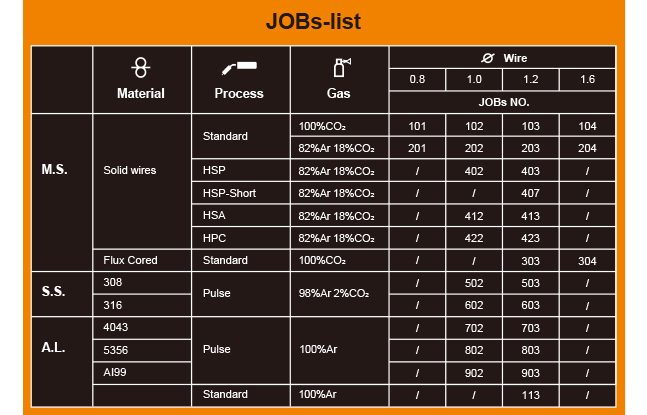

Synergy control with job-list

The Job-lists display is easily and intuitively controlled through its graphical user interface. We assembled the perfect welding curve in every Job-No. for highly efficient multi-process welding of carbon steels and aluminum alloys. Operation is easier than ever before.

Improved Operation Process & Controls

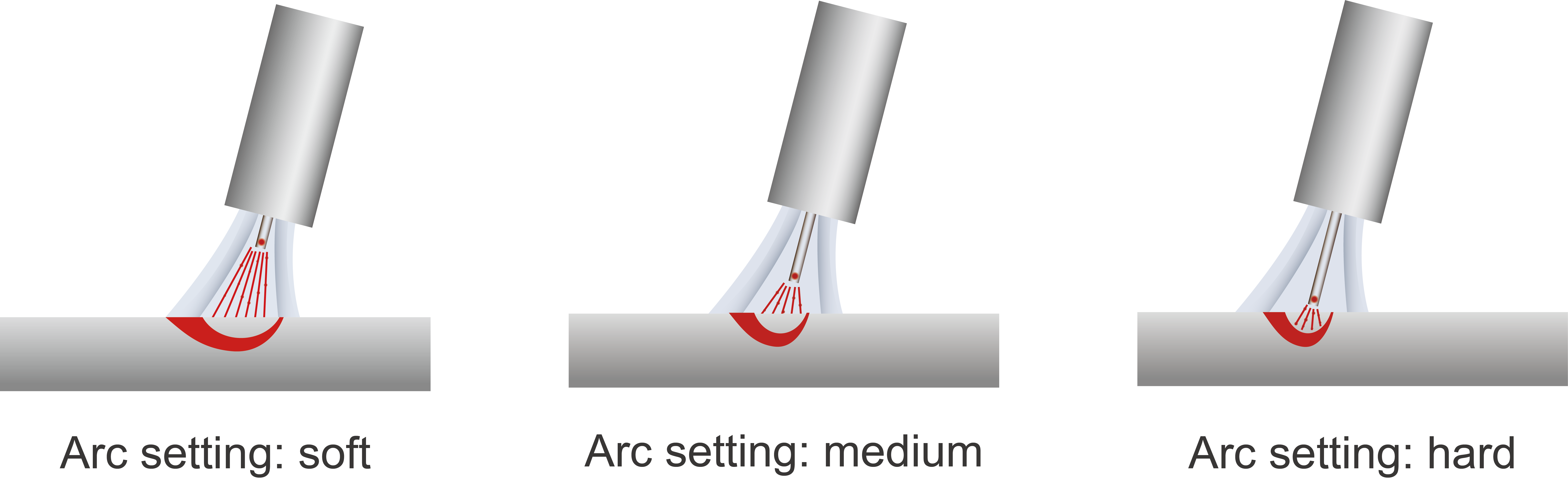

By changing the distance between torch and workpiece. You can now react much more easily to control the arc, such as changing gap dimensions or arc blow, more intuitively and with greater efficiency !

Dynamic control allows the welder, for the first time, to variably adjust a pulse welding machine to a wide range of jobs and welding positions as well as to his personal preferences. The welder can use a controller to directly access the arc characteristic and change it from soft to hard.

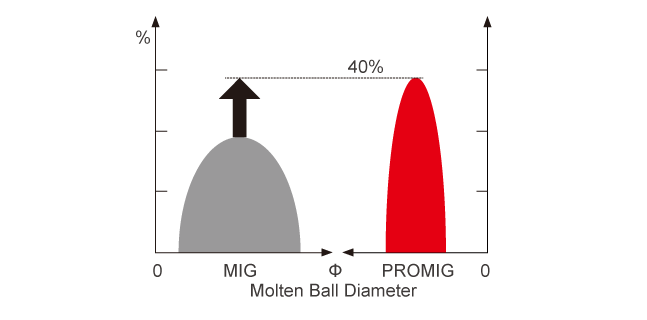

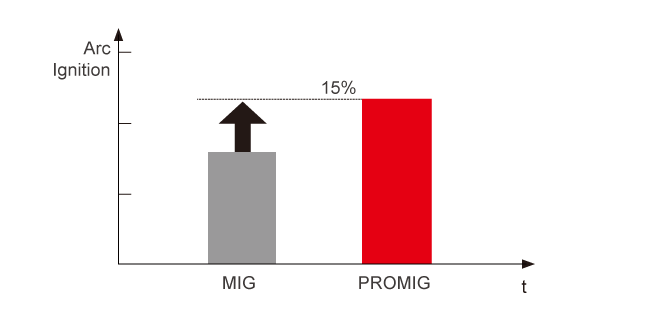

Initial Arc control is used to improve the success rate of arc ignition and form a smaller molten ball. Burn Back control enhances the function of eliminating molten ball, making the secondary arc initial easier.

Better Aluminum Welding Process

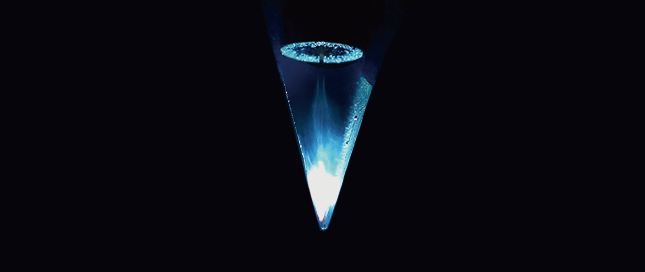

The PROMIG 500SYN DPulse is an upgraded module and machine that is compatible with more advanced pulse processes. Can provide a higher peak current and a larger current difference that is more suitable for aluminum alloy welding, easily triggering a stable arc and cleaning oxides, while generating enough heat to melt the metal and obtain high-quality welds.

With optional Push-Pull gun, the outstanding aluminum welding performance can be achieved much faster and more easily.

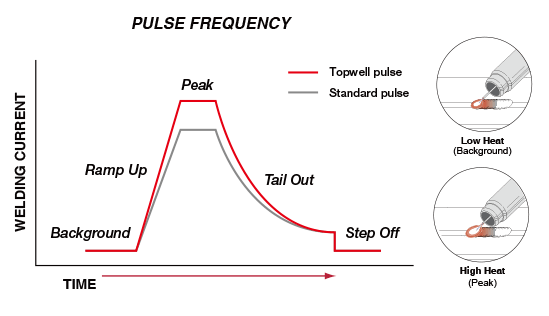

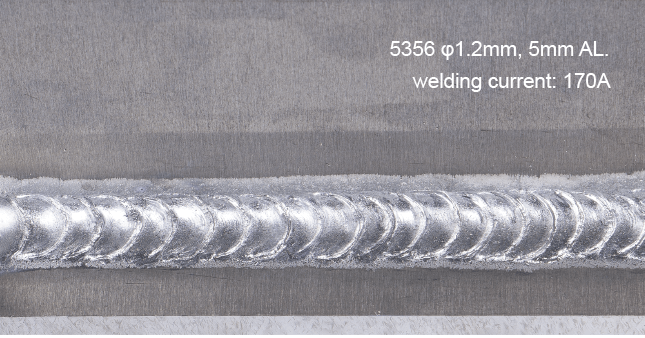

The precise control of pulse period ensures the stable process of droplet transition, with only one drop of metal shooting out from the tip of the welding wire within a pulse period. Therefore, it will not generate a large amount of spatters, even under high current, reducing cleaning work and improving the appearance of the weld.

The powerful data accumulation has shaped the perfect pulse waveform of PROMIG 500SYN DPulse, with multiple welding parameters working together. As the wire speed increases/decreases, the pulse or MIG parameters will also increase/decrease to match the appropriate power required to achieve a more perfect welding curve.

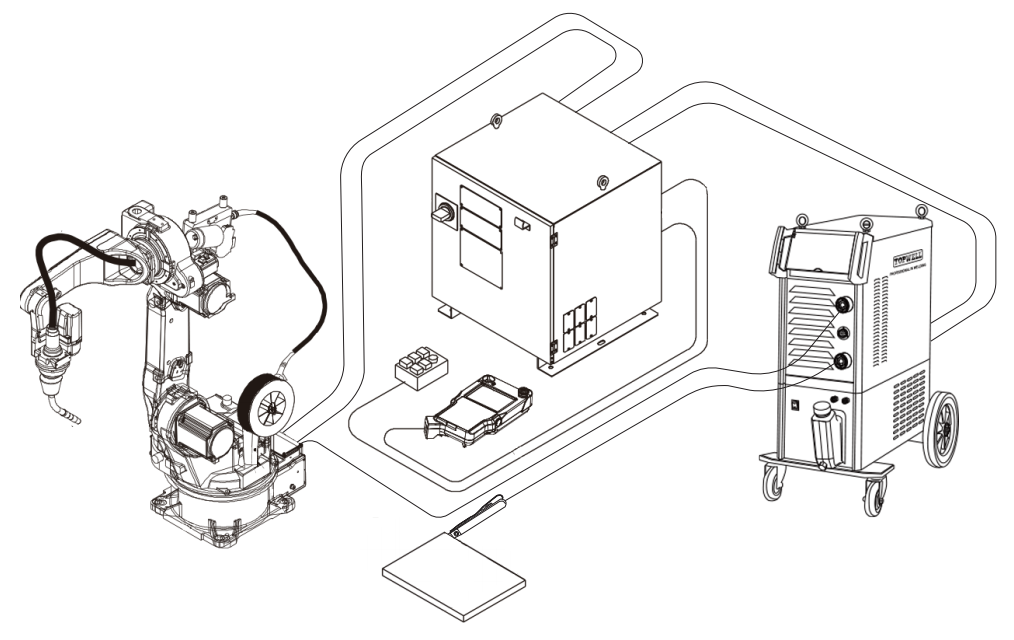

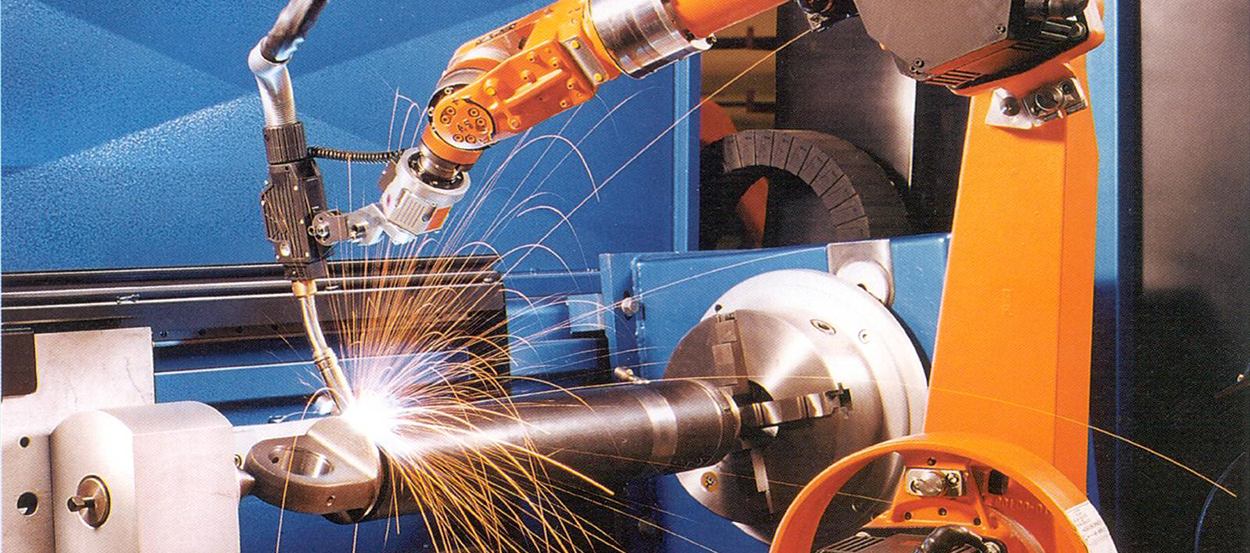

Separated wire feeder & remote control, robotic ready

Robotic with advanced MIG process package, achieve ultra-high efficient welding with perfect welding performance. Optional package for robot interface by Analog connectors or Digital ports including EtherNetlP, DeviceNet, CAN, CANOPEN, RJ485 etc.

| Robot Welding Requirement | |

|---|---|

| Synergy Control | ● |

| Pulse MIG | ● |

| Double Pulse MIG | ● |

| HSP | ● |

| HSA | ● |

| ULS | ○ |

| HSS | ○ |

| HPC | ○ |

| MDP | ○ |

| ● Standard options | ○ Optionally available |

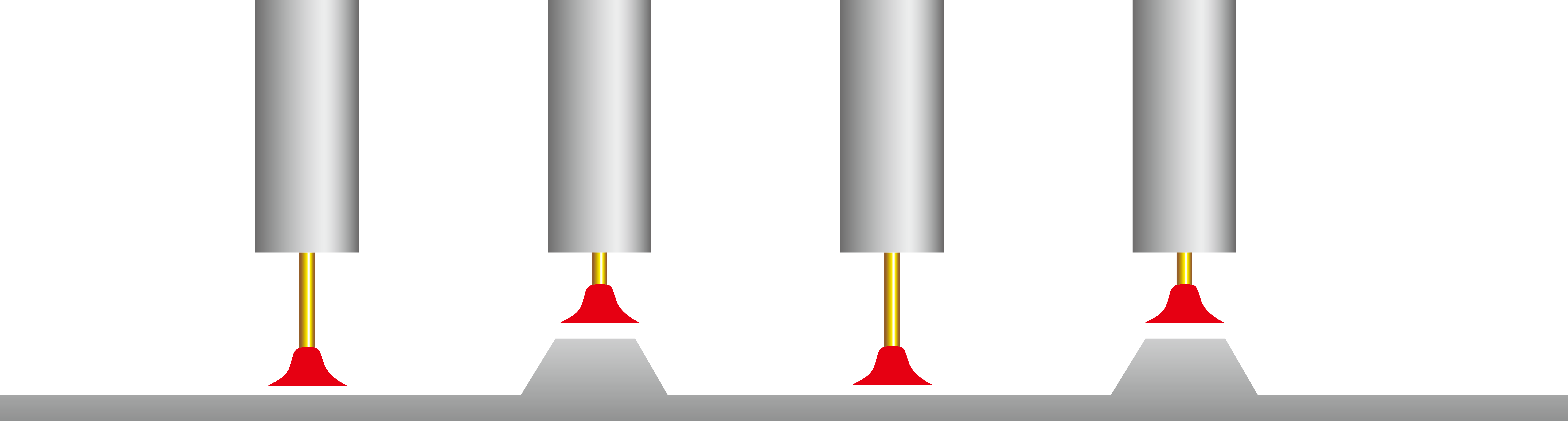

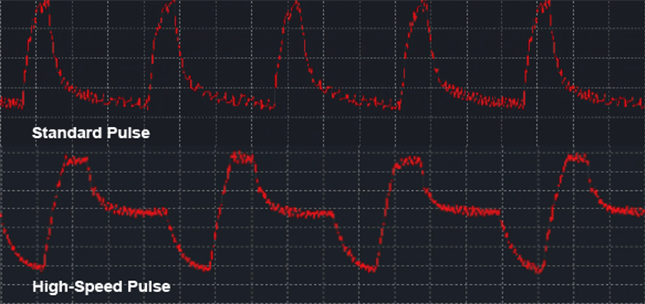

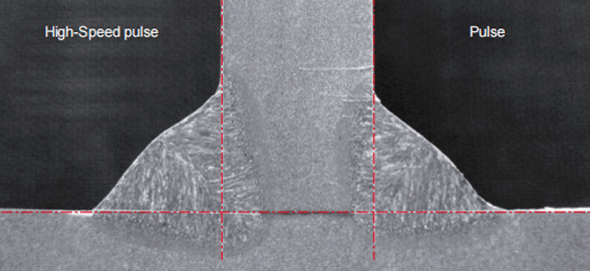

Advanced Technologies for Higher Efficiency

Specifically designed for demanding workshop use, the deposition rate can increase 25~48 % for various materials, whether used in manufacturing thick materials or sheet metal. The High-Speed Pulse(HSP) process enables you to save time, money, and energy compared to traditional pulse welding. This process is ready to raise pulse welding to a whole new level! In general, One pulse melt one droplet, but we increase the submission of these droplets by TOPWELL’s New High-Speed pulse process.The transition will be faster, narrower HAZ zone and deeper penetration!

Get better welding seam Less heat input, less spatters, less rework.

Get higher welding strength Deeper penetration, no undercut defects, higher strength.

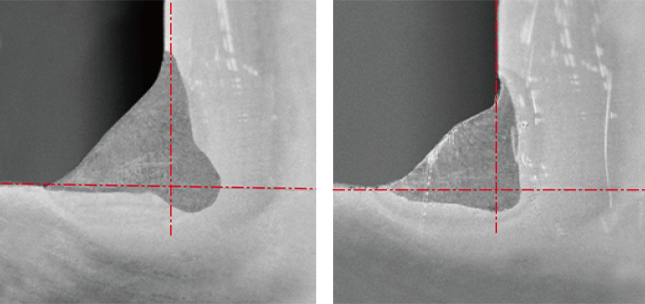

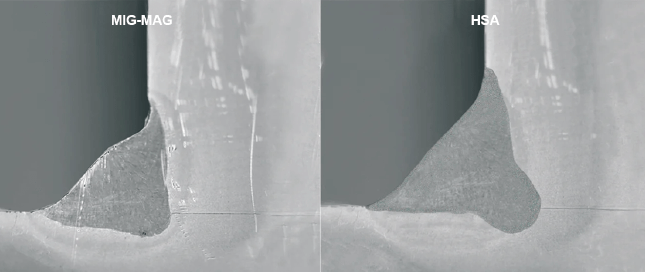

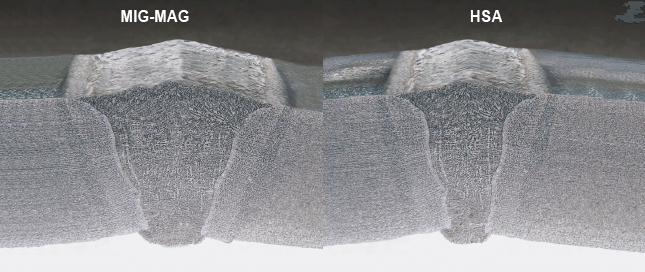

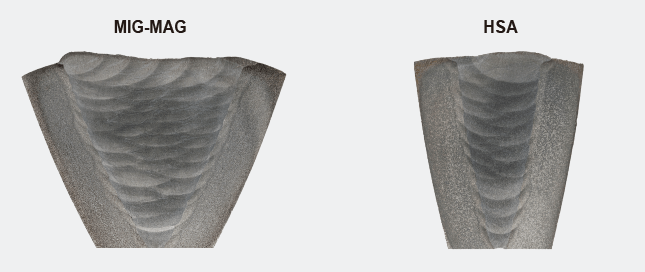

The perfect combination of a highly concentrated and extremely stable arc with high density. HSA delivers deeper penetration, narrower heating zone, allows smaller opening angles for multi-layer welding, significantly improves the welding speed up to 30% faster than conventional MIG-MAG welding. It makes welding more efficient and more economical.

Smaller opening angle

Deeper penetration

More material saving

Higher welding efficiency

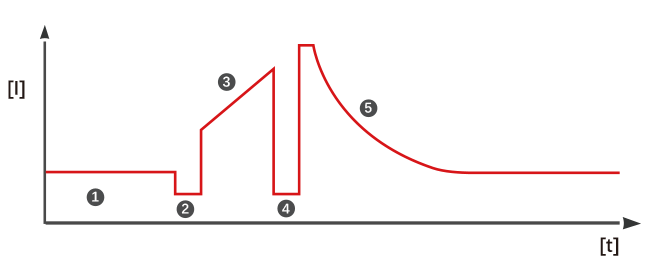

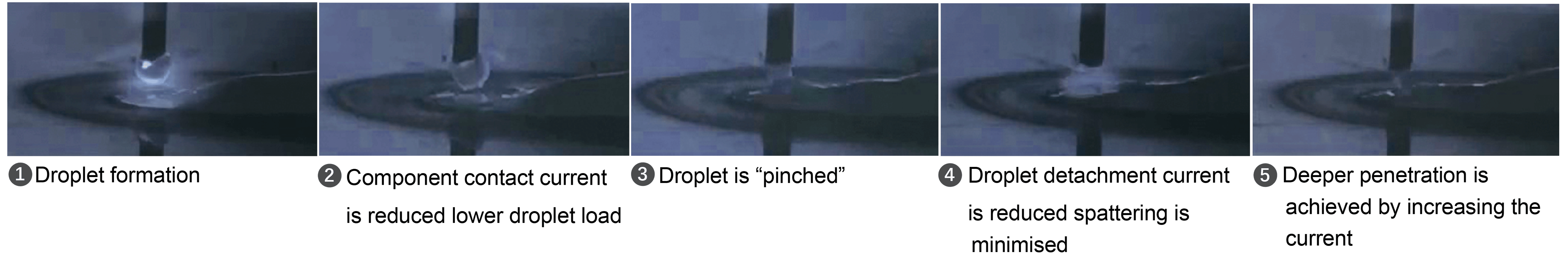

The ULS process is a modified short-arc transfer arc with perfect waveform setting that greatly reduces spatter generation. In the pinch phrase, there is a special current interruption, the energy is extracted under the program setting, avoiding the explosion caused by the large current, and the surface tension of the molten pool warms the generated droplets. Even in CO2 and MAG welding, it can minimize the spatters, which means less rework, fewer rejects, less cleaning required and savings on wearing parts.

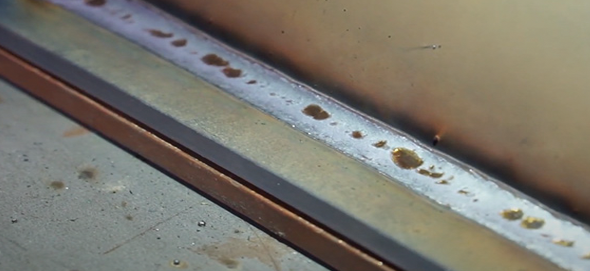

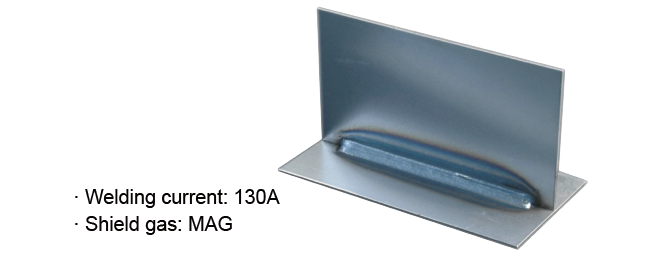

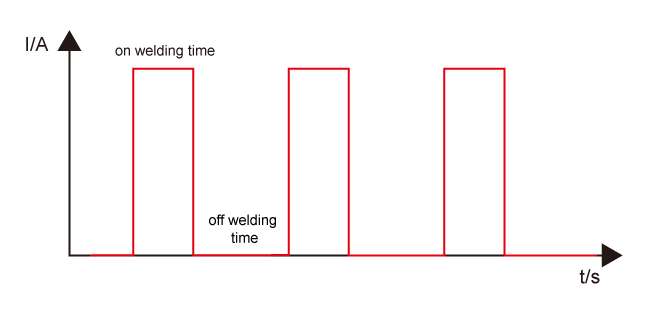

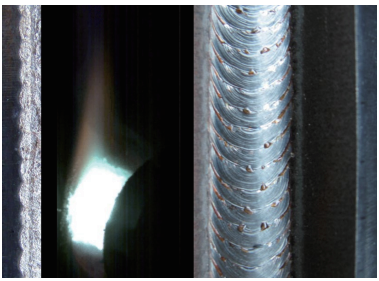

HSS is the high speed spot welding, which is perfectly combining the welding process, arc physics, high dynamic power response and powerful motor control technology, short in arc ignition time and arc ending time, a welding spool can be formed swiftly. A spot welding cycle is quickly completed, cycle over and over, by adjusting the time gap with the robot to get the fish scale you wish, weld seam is clear and beautiful.

Tack welding: by robot

Widely applied on the thin (≤2mm thickness) pipes or frame/structure welding jobs.

The key is synergetic waveform controlled welding process control variants applied in MIG welding which are Pulse(spray arc) and short-circuit transfer types in one duty cycle. It delivers exceptional directional stability, deep penetration and free-spatters.

The secret is the combination of two processes: one is the high energy phase to heat up the material quickly. Topwell's control technology ensures a perfect transition to the rapidly reduced energy phase. It ensures reliable penetration, precisely sized weld filling and a near- optimal throat thickness.Vertical-up welding with Topwell's HPC process is significantly much faster and simpler than classical "X-Mas tree".

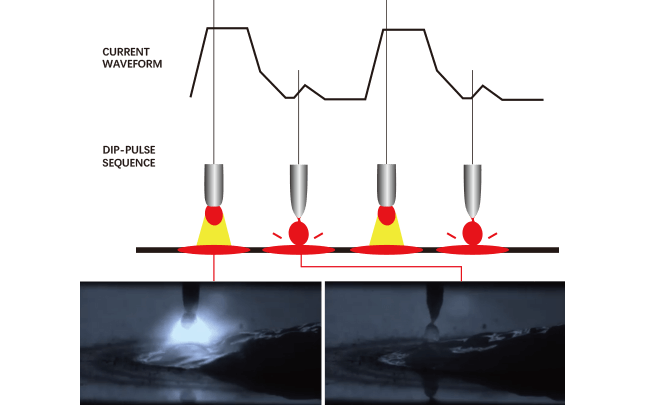

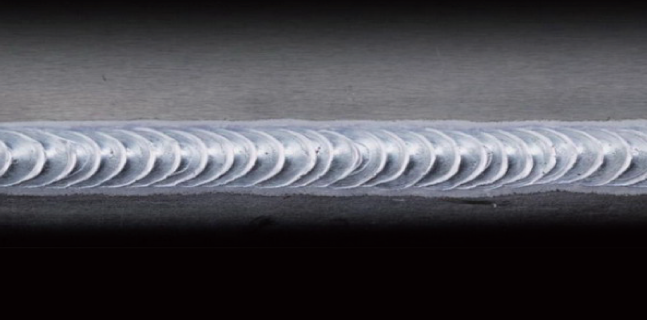

MDP is Micro Double Process, ultra-precise on the synergy Pulse wave-form controlled process-control, freely adjust the weld seam chevrons from coarse to fine. The key is that when the high and low pulses alternate, there is no droplet formation in the low pulse phase. The advantage of MDP are precise energy input, low distortion, perfect TIG-like welding appearance easily produced by anyone, and the welding productivity can up to twice as quick as the conventional TIG. MDP is particularly suitable for thin to medium-walled (1-8mm) Aluminum, Steel, and CrNi applications, like frames, tables, beds, and furniture structures.

Improved Operation Process & Controls

LET'S STAY IN TOUCH

Get updates on sales specials and more

FOLLOW US

We want to hear from you!

Copyright © 2022 HANGZHOU TOPWELL TECHNOLOGY CO.,LTD. | 浙ICP备2022006748号