Processes:

SAW,

SMAW,

CAC-A

Applications:

Structural Steel

Process and Power Generation

Wind Tower Fabrication

Heavy Equipment

Offshore

Pipe Fabrication

Rated Output at 40℃ (104℉):

ARC1000 PLUS (DC/XD): 1000A/50V/100%

ARC1250PLUS (DC/XD): 1250A/50V/100%

Input Power:

340-460V/3-PH/50-60Hz

Overview of Topwell SAW system

| SAW system | DC series | XD series |

|---|---|---|

| Available Material | Unalloyed and low alloy steels

|

Unalloyed and low alloy steels Nikel-based alloys |

| Available wire diameter | 2.0-6.0mm | 1.2-6.0mm |

| Wire feed control technology | CC |

CC/CV use arc voltage sensing technology |

Advanced Features and Benefits

Precision Energy Control for Thin Plates and Nickle-based Alloy Welding

In constant voltage mode, welding current is precisely regulated to support high-precision welding processes. This allows for the use of welding wires as fine as 1.2mm, producing high-integrity welds on thin-gauge sheet metal. The system also delivers superior performance in welding nickel-based alloys, maintaining stability even at elevated temperatures and providing exceptional oxidation resistance. Through accurate control of linear heat input, the heat-affected zone is minimized, thereby reducing distortion and mitigating the risk of cracking.

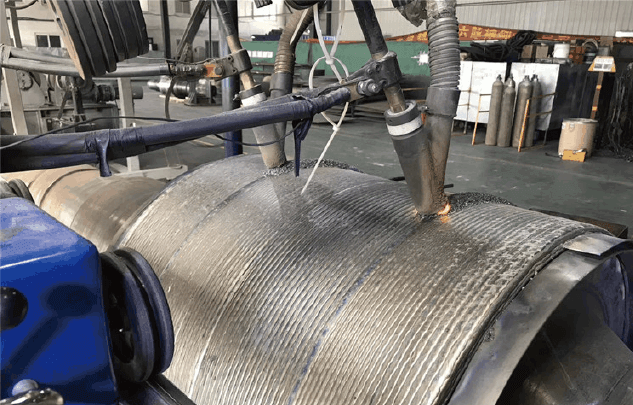

Hardfacing with High Deposition and Aesthetic Formation

• Produces consistent, high-strength weld seams;

• Attains 60–80% deposition efficiency for material savings;

• Avoids hydrogen cracking and porosity formation;

• Decreases grinding and eliminates extra passes.

Ready for IoT Connection

Versatile IoT interfaces, including communication, sensor, user interaction and power supply interfaces, allows unlimited possibility of interconnections, so as to meet the needs of modern industrial production.

User- friendly Controller

Topwell offers controllers with user-friendly panel, automation interface, memory function and build-in self-protection system.

LET'S STAY IN TOUCH

Get updates on sales specials and more

FOLLOW US

We want to hear from you!

Copyright © 2022 HANGZHOU TOPWELL TECHNOLOGY CO.,LTD. | 浙ICP备2022006748号