MASTERTIG-320CT

The total solution of TIG welding

Application:

Pipe

Tube

Pressure Vessel

Stainless Steel Product

Aluminum Ship Repair

Processes:

DC TIG

AC TIG

MIX TIG

Stick (SMAW)

Input Power:

400V, 3-Phase

Amperage Range:20-320A

Rated Output at 40℃ (104℉):

320A at 22.8V @60% Duty Cycle

Weight:75kg

Unique MIX TIG

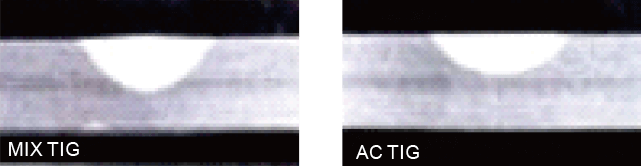

Everybody knows the AC current has a good clearance and DC current gets a good penetration. What if mix the AC and DC?

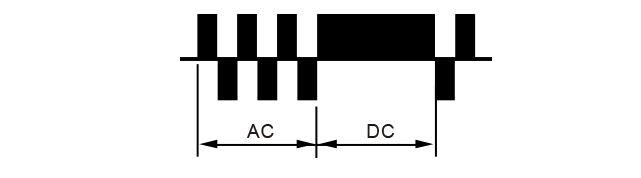

MIX TIG is TOPWELL’s unique technology, it contains AC current and DC current in one duty cycle.

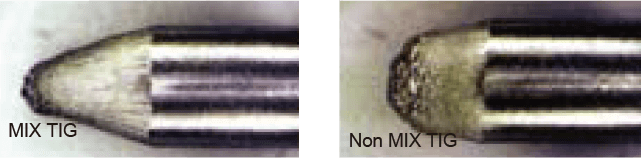

That keeps the advantages and reduces disadvantages from each other. Using the MIX TIG technology gets an excellent arc concentration and can be carried out the excellent welding performance, especially for thick plates.

MIX TIG advantage

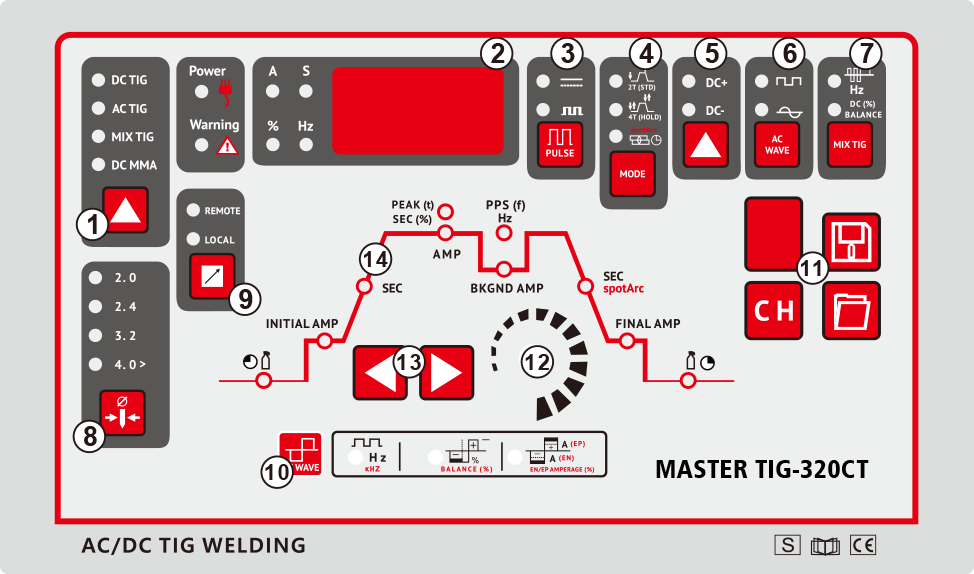

General View Of Control Panel

1. Welding Process

DC TIG/AC TIG

MIX TIG/DC MMA

2. Ammeter/Voltmeter Display

3. Pulser Control

Pulse ON/OFF selection.

4. Mode2T(STD)/4T(HOLD)/Spot Arc

5. Arc Ignition PolarityDC+/DC-

6. AC Waveshape types

Advanced Squarewave

Triangular Wave

7. MIX TIG

MIX Frequency: 0.1Hz~5Hz

8. Tungsten Electrode Dia.

From 2.0mm to 4.0mm

9. Remote: used for foot pedal or Remote torch.

Local: adjusted Currents by face panel

10. AC Waveshape

AC Frequency Range: 20Hz~200Hz

AC Clean Width(AC Balance): +40~-40

AC Clean Ratio(AC Bias)%:+30~-50

11. Memory

12. Encoder Control

13. Select welding parameters button

14. Function Sequence

Complete AC Waveshape Controls

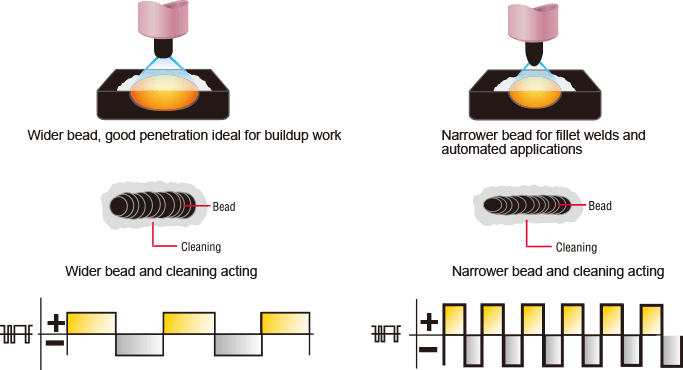

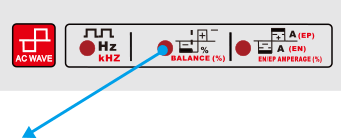

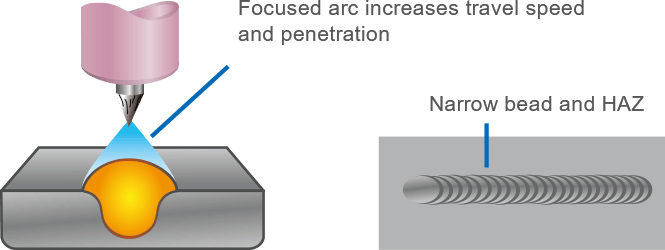

AC Frequency control

Controls the width of the arc cone. Increasing the AC Frequency provides a more focused arc with increased directional control.

Note: Decreasing the AC Frequency softens the arc and broadens the weld puddle for a wider weld bead.

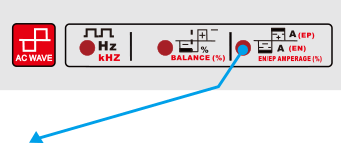

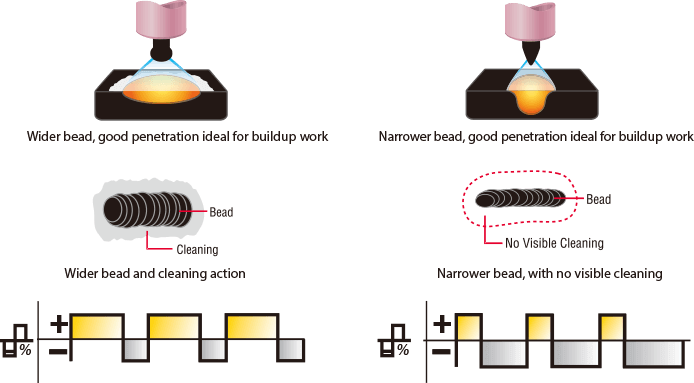

AC Balance Control

Controls arc cleaning action. Adjusting the % EN of the AC wave controls the width of the etching zone surrounding the weld.

Note: Set the AC Balance control for adequate arc cleaning action at the sides and in front of the weld puddle. AC Balance should be fine tuned according to how heavy or thick the oxides are.

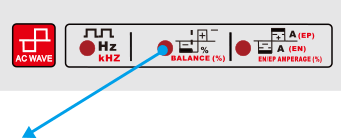

Amplitude Control

Adjusts the ratio of EN to EP amperage to precisely control heat input to the work and the electrode.

Note: EN amperage controls the level of penetration, while EP amperage dramatically effects the arc cleaning action along with the AC Balance control.

Pulsed TIG Controls

The Pulsed TIG function switches the amperage from a high(peak) to a low(background) at a set rate(PPS). Pulsing can reduce heat input by lowering the average amperage,increasing control of the weld puddle, penetration and distortion. The following parameters can be adjusted for desired results:

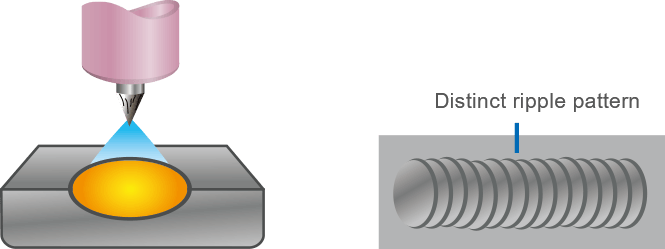

Low-Speed Pulse

1 to 10 pulses per second(PPS) will produce a distinct ripple pattern in the weld bead. Can be used to time filler addition,reduce distortion and improve control.

High-Speed Pulse

100 pulses per second(PPS) and higher helps to focus the arc for increased stability, penetration an d travel speed. Increased puddle agitation improves weld microstructure.

LET'S STAY IN TOUCH

Get updates on sales specials and more

FOLLOW US

We want to hear from you!

Copyright © 2022 HANGZHOU TOPWELL TECHNOLOGY CO.,LTD. | 浙ICP备2022006748号