STC-205Di

3-IN-1 Multi-process: DC TIG + Plasma Cutting

Application:

Metal Fabrication

Maintenance and Repair

Auto Body

Light Industrial

These Materials:

DC TIG, AC TIG,

MIX TIG, MMA(Stick)

Plasma Cutting

Input Power:

230V or 115/230V, 1-Phase

Amperage Range:

PAC: 20-50A/MMA: 10-160A

Rated Output at 40℃ (104℉):

TIG: 200A at 18V @60% Duty Cycle

PAC:50A at 100V @60% Duty Cycle

Weight: 15kg

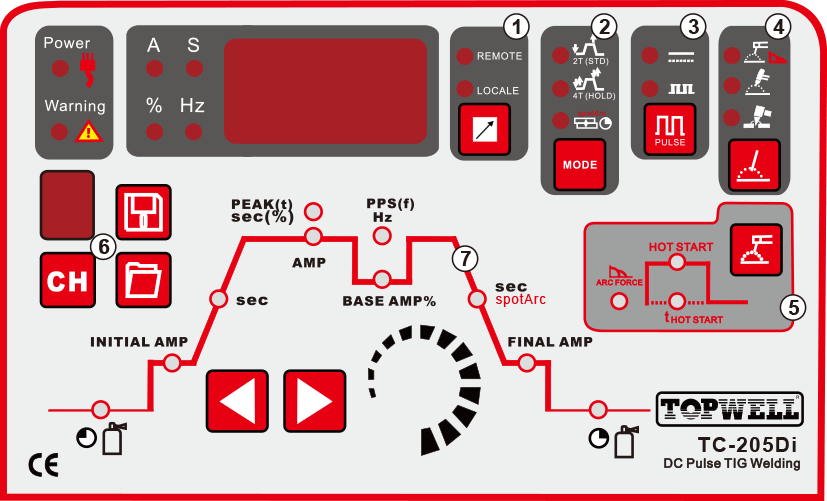

General View Of Control Panel

1. Remote:used for foot pedal or Remote torch

Local:adjusted Currents bu face panel

2. 2T/4T holding mode or Spot Welding mode selection

3. Pulse ON/OFF selection

4. Process selsction;

5. ARC FORCE/HOT START

6. Memory with capacity of 10 sets parameters

7. Function Sequence.

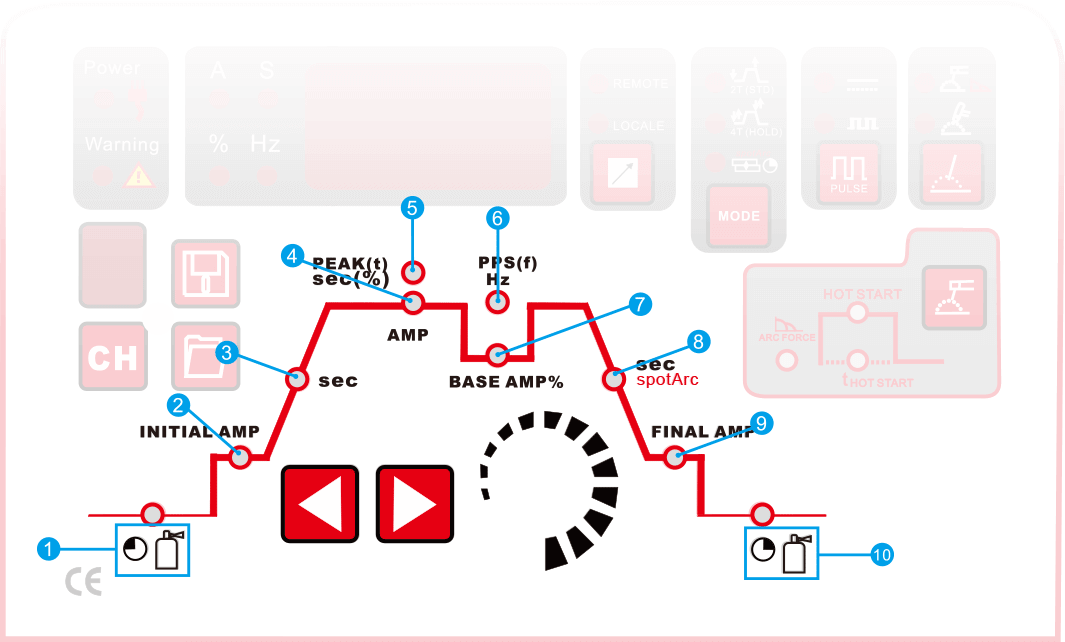

Function Sequence

1.Gas pre-flow time(TIG)

Absolute setting range 0.1s to 5.0s (0.1s increments).

2.Igni tion current(TIG)

Percentage of the main current.

Setting range 1% to 100%(1% increments).

3.Up-slope time(TIG)

Setting ranges:0.00s to 20.0s(0.1s increments).

The up-slope time can be set separately

for non-latched and latched.

4.Main current(TIG)/pulse cuttent

I min to max(1 A increments)

Main cuttent(MMA)

I min to I max(1 A increments)

5.Pulse time

Pulse time setting range:0.01s to 9.99s(0.01s increments)

TIG pulses

The pulse time applies to the main cuttent phase(AMP) for pulses.

TIG AC Special

The pulse time applies to the AC phase for AC special.

6.Pulse break time

Pulse break setting range:0.01s to 9.99s (0.01s increments).

TIG pulses

The pulse break time applies to the secondary current phase(AMP%).

TIG AC Special

The pulse time applies to the AC phase for AC special.

7.Secondary current(TIG)/pulse pulse pause current

Setting range 1% to 100% (1% increments).

Percentage of the main current.

8.Down-slope time(TIG)

0.00s to 20.0s (0.1s increments).

The down-slope time can be set separately for non-latched and latched.

9.End-crater current(TIG)

Setting range 1% to 100%(1% increments).

Percentage of the main current.

10.Gas post-flow time(TIG)

Setting ranges:0.1s to 20.0s(0.1s increments).

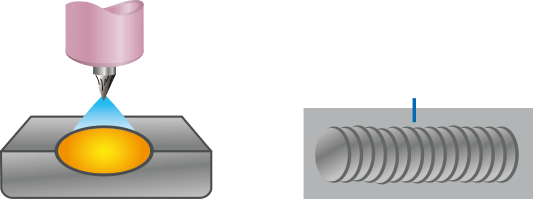

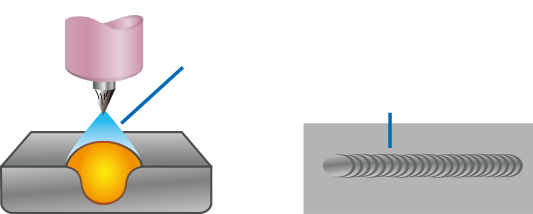

Pulsed TIG Controls

The Pulsed TIG function switches the amperage from a high(peak) to a low(background) at a set rate(PPS). Pulsing can reduce heat input by lowering the average amperage,increasing control of the weld puddle, penetration and distortion. The following parameters can be adjusted for desired results:

Low-Speed Pulse

1 to 10 pulses per second(PPS) will produce a distinct ripple pattern in the weld bead. Can be used to time filler addition,reduce distortion and improve control.

High-Speed Pulse

100 pulses per second(PPS) and higher helps to focus the arc for increased stability, penetration an d travel speed. Increased puddle agitation improves weld microstructure.

CUT PERFORMANCE

| Capacity | Thickness | Cut speed |

|---|---|---|

| Recommended | 8mm | 500mm/min |

| 13mm | 250mm/min | |

| Severance(hand cutting) | 16mm | 125mm/min |

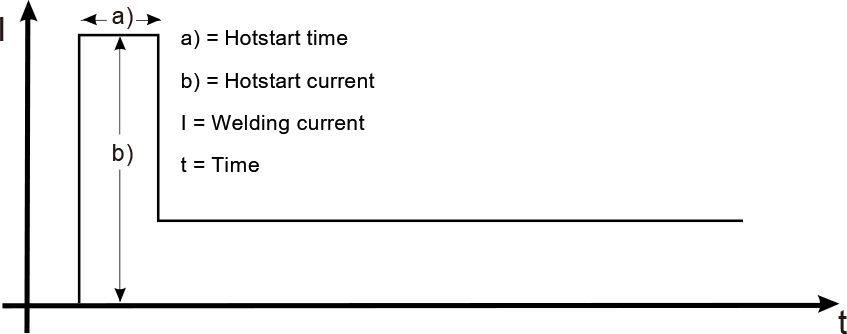

Hot start

function reliably ignites the electrode and melts perfectly to ensure the best quality even at the start of the seam.This solution makes lack of fusion and cold welds a thing of the past and significantly reduces weld reinforcement. Adjust the hot start current here and the time here.

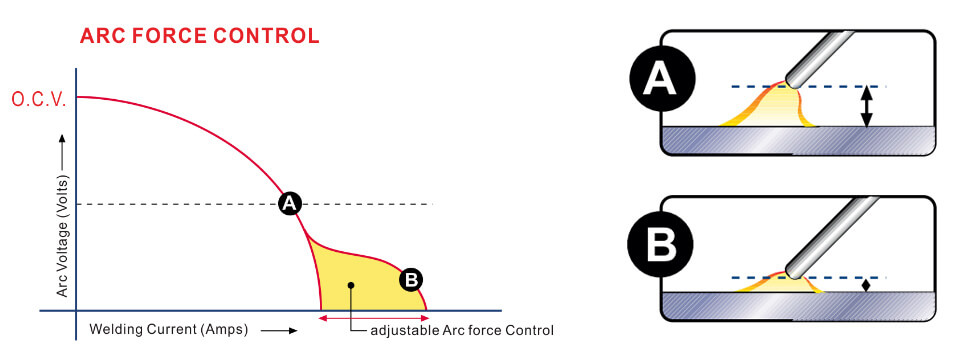

Arcforce correction (welding characteristics)

Arcforce is a setting that allows you to adjust the arc to soft smooth arc to a more aggressive digging arc. Setting high is to bump up amperage when you have a really tight arc so that you keep welding.

LET'S STAY IN TOUCH

Get updates on sales specials and more

FOLLOW US

We want to hear from you!

Copyright © 2022 HANGZHOU TOPWELL TECHNOLOGY CO.,LTD. | 浙ICP备2022006748号