PROCUT-105HD

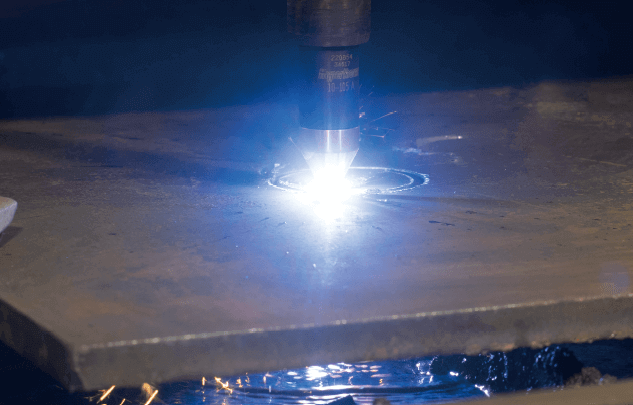

HD CNC Cutting, Great for a wild thickness from 1mm to 15mm

Application:

Home workshop

Metal workshops

Light fabrication,

Repair and maintenance

These Materials:

Mild Steel

Brass

Copper

Aluminum

Input Power:

340V-460V ,3-Phase

Amperage Range: 30-105A

Rated Output at 40℃ (104℉):

105A @ 100% Duty Cycle

Weight: 45KG

Excellent Cutting Performance

Maximum productivity

- The cutting speed of dross free can reach 900mm/min for 16mm mild steel.

Higher reliability and stability

- Designed with 100% duty cycle for the most demanding production environments.

- Designed and tested as the TOPWELL PROCUT series product for superior reliability in the most demanding cutting environments.

Long life consumables

- Reduce costs with long consumables life and more up time.

Economic

- Low maintenance for maximum uptime.

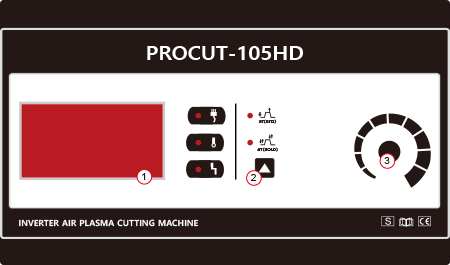

General View Of Control Panel

1.Ammeter/Voltmeter Display

2.Encoder Control

3.Mode:2T(STD)/4T(HOLD)

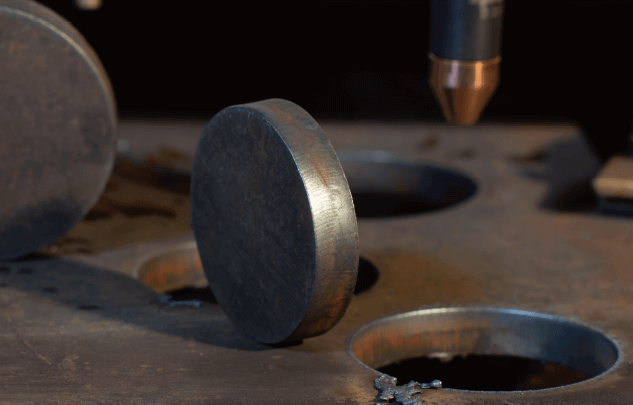

Cutting Capacity (Carbon Steel)

| Capacity | Thickness | Cut speed |

|---|---|---|

| Dross free(CNC) | 16mm | 900mm/min |

| Pierce* | 22mm | |

| Cut angle(ISO9013) | Range 2 | |

| Severance(Hand cutting) | 50mm | 125mm/min |

*Pierce rating for handheld or with CNC torch height control

| Gouge capacity | Removal rate | Groove profile |

|---|---|---|

| Plasma gougingn | ||

| Typical gouge | 8.8kg/h | 5.8mm Dx 7.1mm W |

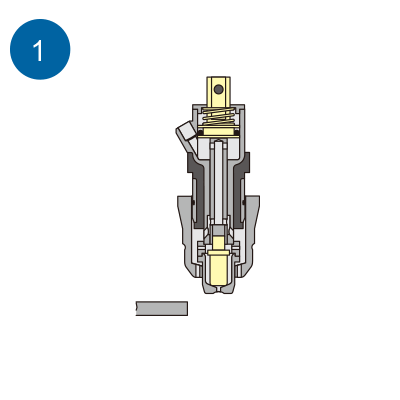

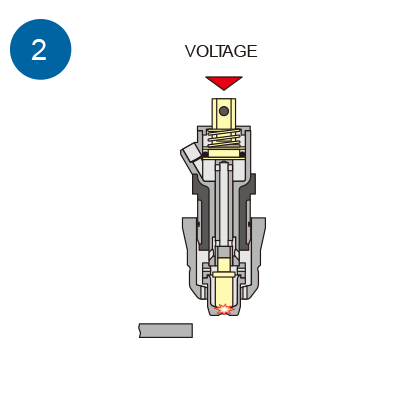

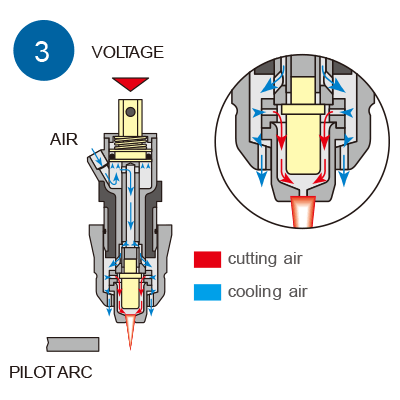

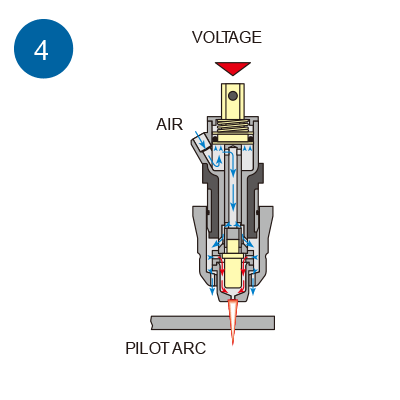

Non-HF Arc Ignition System

Torch off.

By pressing the trigger the torch will be fed by the current thus causing a temporary short circuit betweenelectrode and tip.

The air then pushes up the small piston, thuscreating, between the electrode and the tip, the distance needed to strike the pilot arc

By positioning the torch on the part to be cut, theplasma arc will strike..

Torches with pilot arc cut in without high frequency.

Less electromagnetic disturbance, with consequent absence of problems for any electronic, radio, television, telephone and computer systems in the vicinity of the cutting positions. Less electric stress on the torch - and on the respective connecting cables - due to the absence of the high voltage necessary for striking the arc Greater simplicity in comparson with other torches(without high frequency) on the market,with a consequent decrease of the risks of jamming in the mechanical pneumatic movement for striking the arc. Subject to wear (electrode, tips, nozzles, diffusers etc.), thanks to the better cooling of the torch obtained by reducing the insulating thicknesses (without endangering the safety parameters).

LET'S STAY IN TOUCH

Get updates on sales specials and more

FOLLOW US

We want to hear from you!

Copyright © 2010 - 2017 www.cn-topwell. All Rights Reserved