Better Aluminum Welding Process

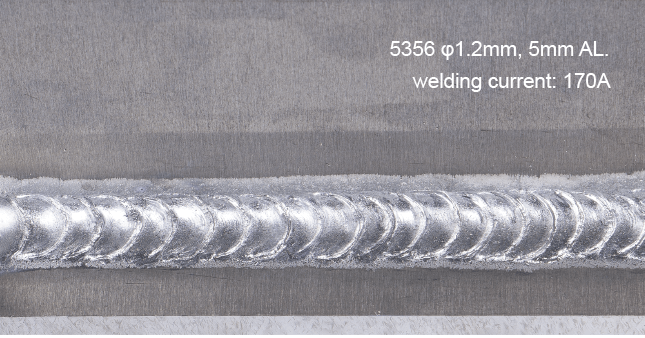

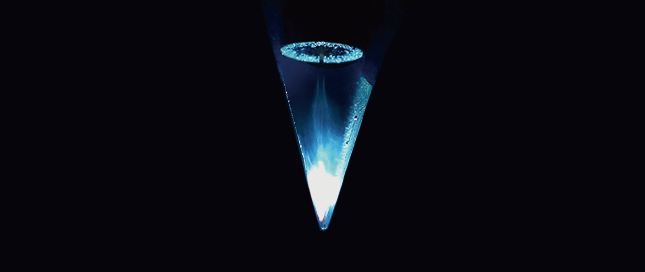

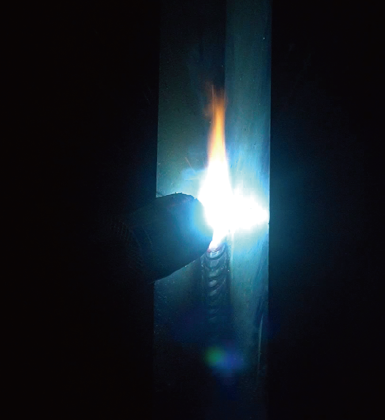

The Improved Pulse Arc

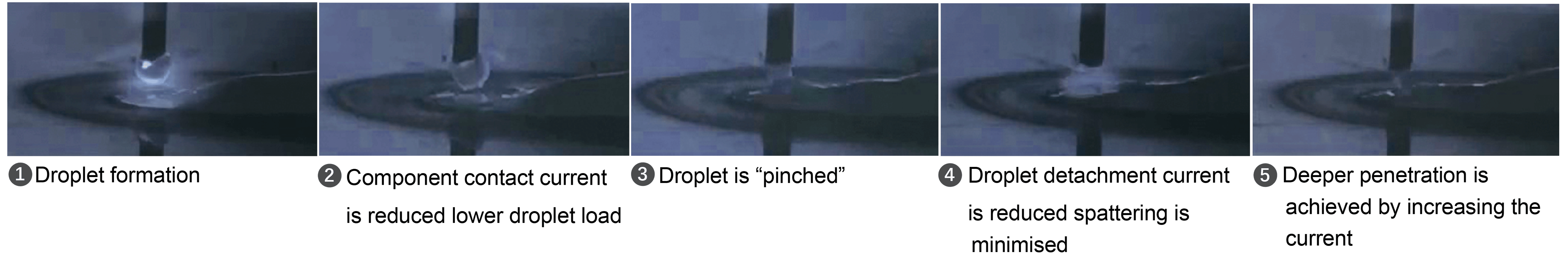

Benefited by the full-digital controller of the Pulse Arc process, it delivers:

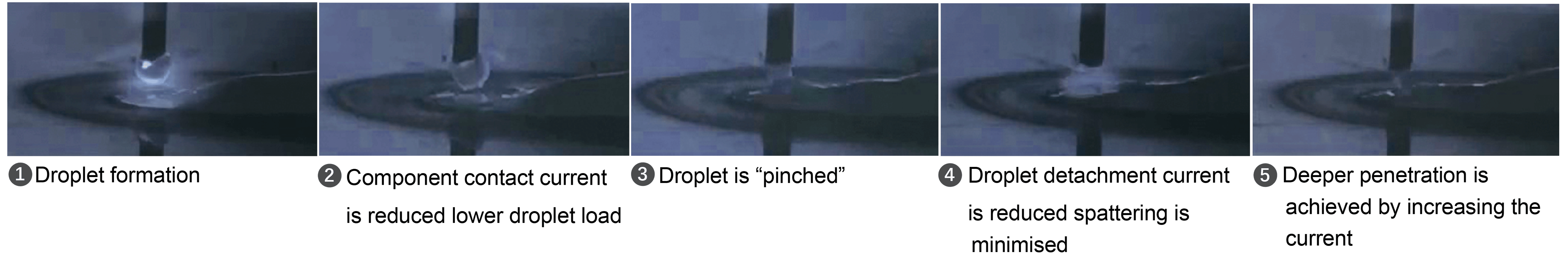

Stable process by the controllable, fast & high-intensity pulse energy;

Precise droplet detachment due to the soonest and powerful electromagnetic pinch effect;

Besides, by the refined and extensive expert database continually, always the Pulse Arc waveforms also updated accordingly.

As a result, it achieved deeper, focused penetration with minimal thermal stress, making it the ideal solutions for less-distortion, spatters-free welding applications especially the Aluminum welding jobs.

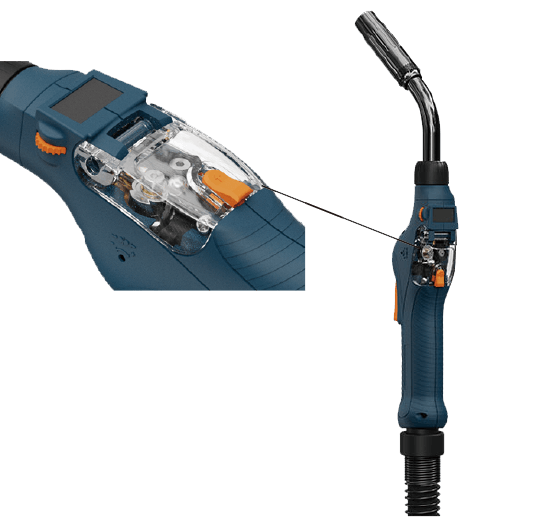

Premium push-pull gun

Using the most durable motor and drive design, and installing the wire drawing motor close to the welding position, the wire feeding is smoother and less likely to get blocked, especially in aluminum welding conditions, which improves wire feeding performance and arc stability.

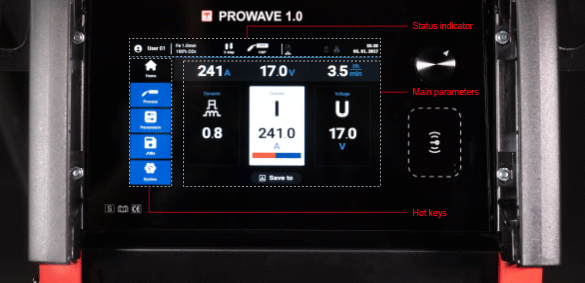

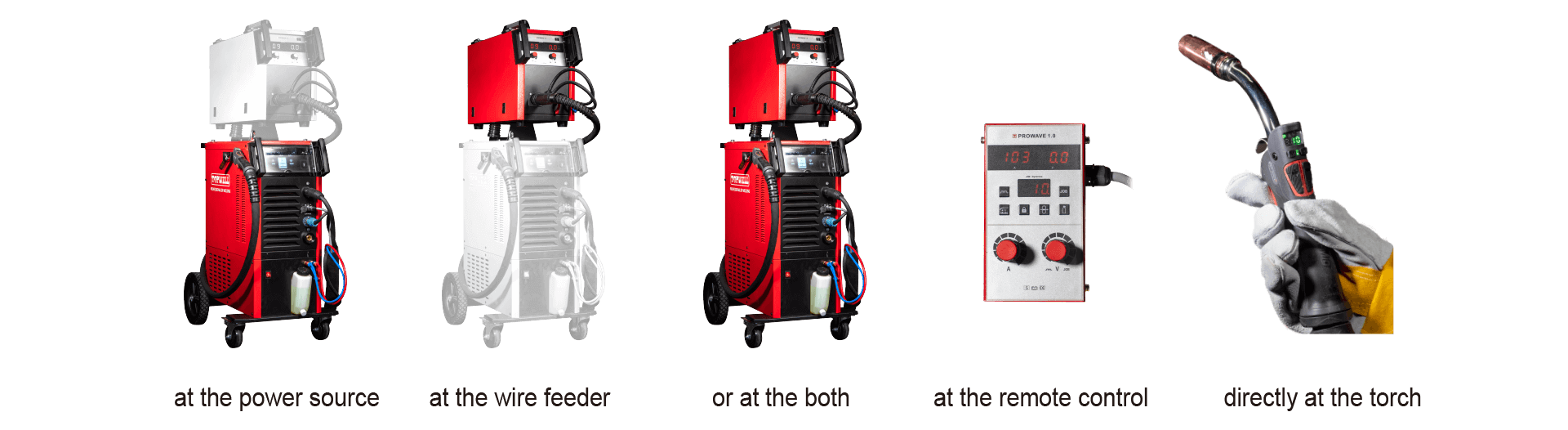

Equipped with LCD screen display and function keys, it can communicate with the power machine to adjust welding procedures and parameters. Communication between the digital welding torch and machine enables enhanced the synergy welding, as the wire speed increases/decreases, the MIG parameters increase/decrease to match the appropriate power required.

Advanced Technologies for Higher Efficiency

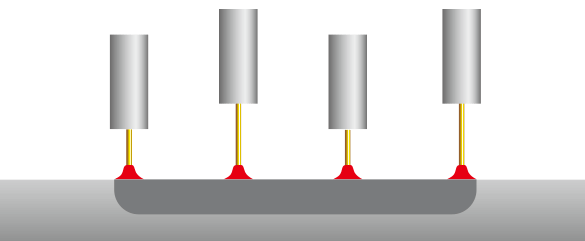

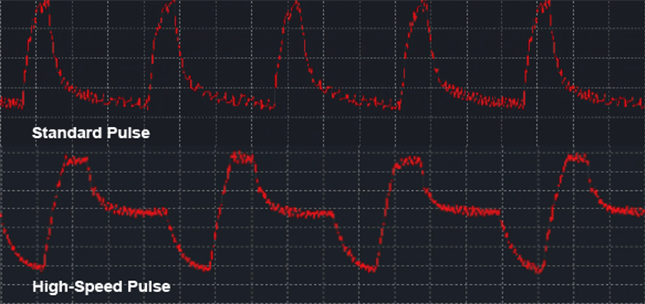

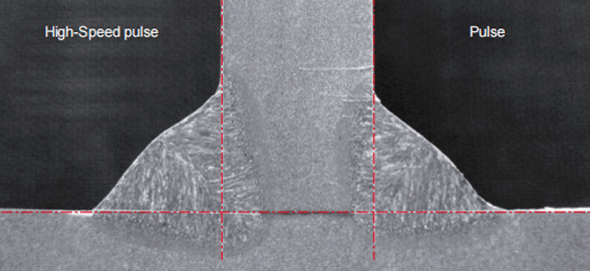

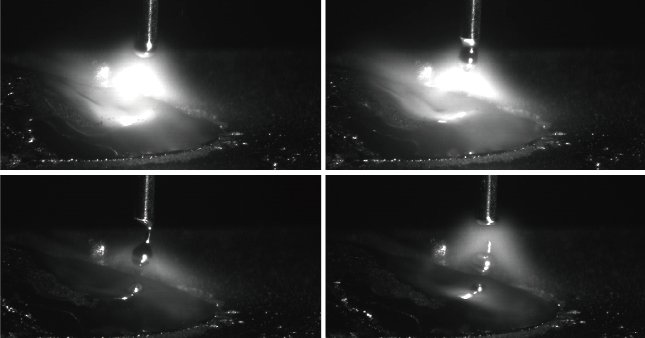

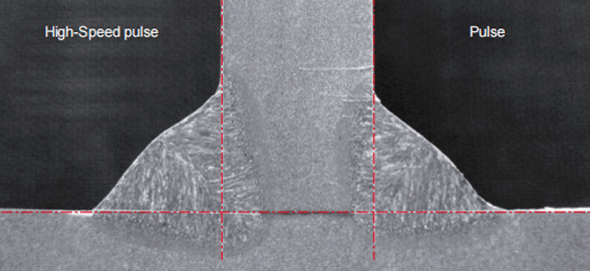

HSP (High Speed Pulse) - Ultra High Deposition Rate

Compared to a standard pulse process, the HSP extends its transition to a virtually flowing material transition to the work pieces, which boosts deposition rates by 35% while ensuring smooth, spatter-free seams. It helps users to save time, money, and resource as no reworks are required.

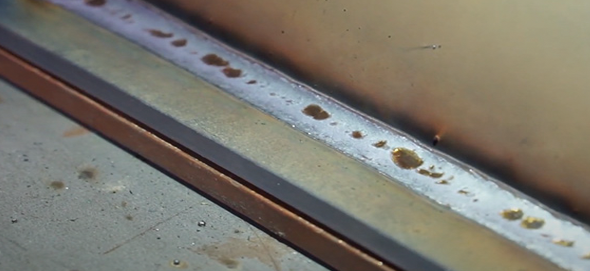

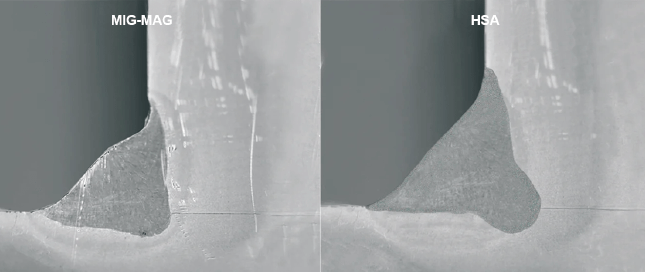

Get better welding seam

Less heat input, less spatters, less rework.

Get higher welding strength

Deeper penetration, no undercut defects, higher strength.

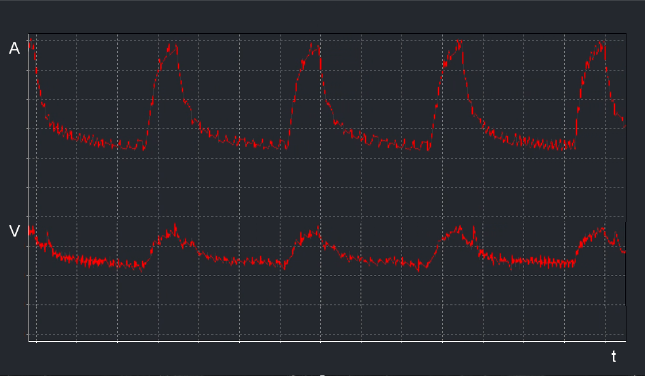

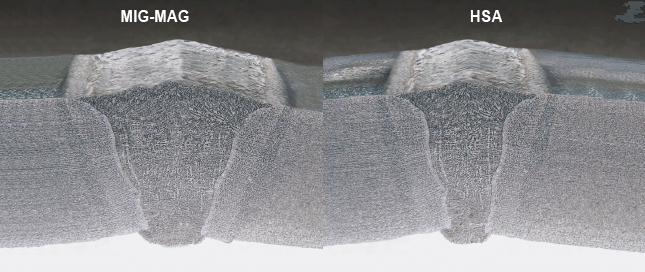

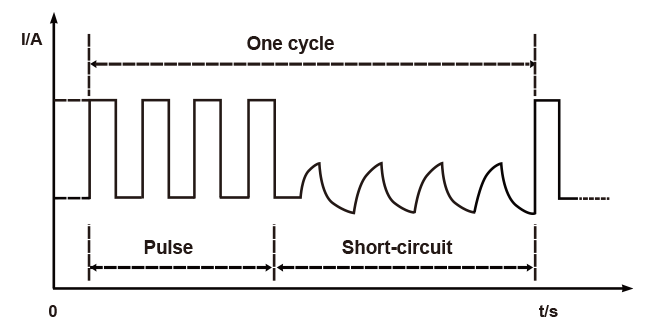

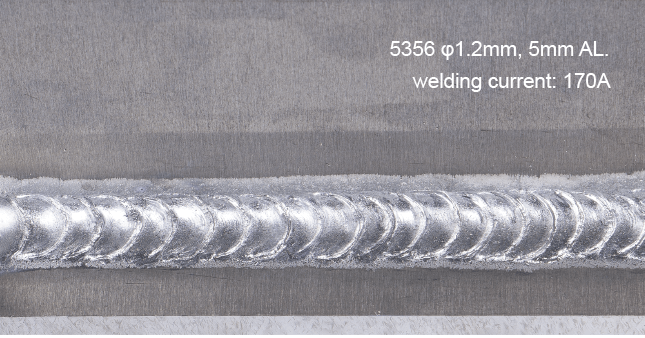

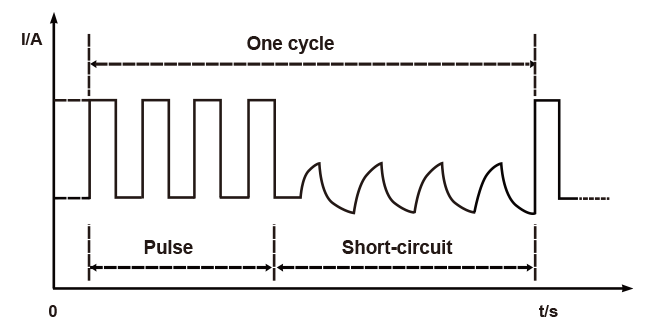

HPC (Hybrid Pulse Control) - Excellent in All-position Welding

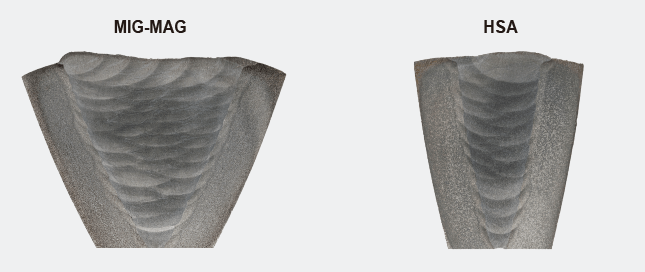

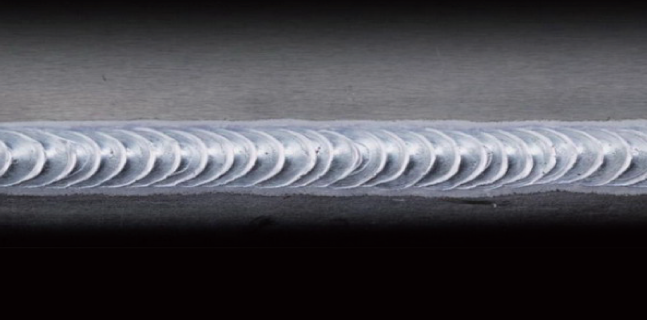

HPC--Hybrid Pulse Control is an advanced hybrid process that integrates Pulse and Short-Circuit transfer methods. By alternating between these two modes, the molten pool is heated and cooled periodically, creating a distinct "fish-scale" ripple pattern. The frequency and duty cycle can be precisely fine-tuned to shape the bead appearance as required. This exceptional puddle control makes HPC ideal for all-position welding, particularly for challenging vertical-up applications.

The specialty of HPC-Vertical Up lies in two processes: one is to heat up the material with high energy, and another is to steeply lower the heat to contribute to the well-formation of seams within a short time.

It ensures a reliable penetration, precisely sized weld fillings, and a near-optimal throat thickness and is faster and easier than the conventional "X-Mas tree".

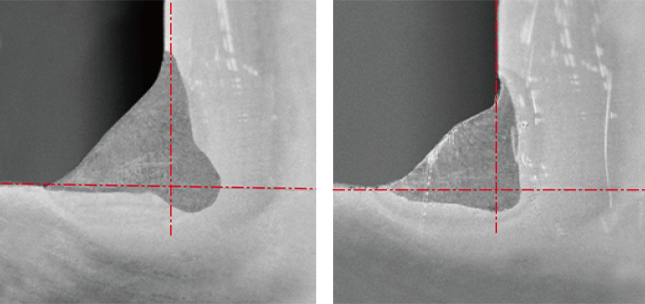

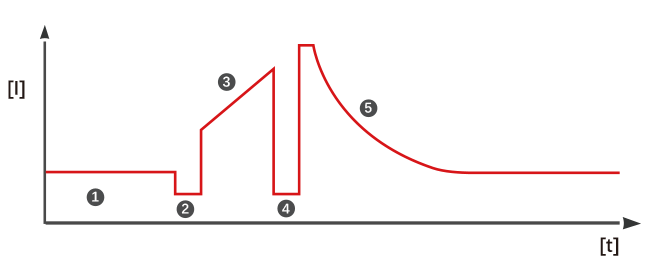

MDP (Micro Double Process) - TIG alike Results and Faster

With MDP, weld seam can be improved from coarse to fine. The key is that there is no droplet formation in the low pulse phase when the high and low pulses switches. Thanks to the precise energy input, MDP can deliver perfect TIG-like welding appearance but is twice faster than TIG. MDP is particularly suitable for thin to medium-walled (1-8mm) Aluminum, Steel, and Cr-Ni applications, like frames, tables, beds, and furniture structures.

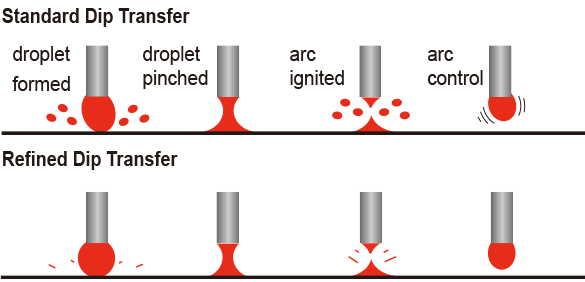

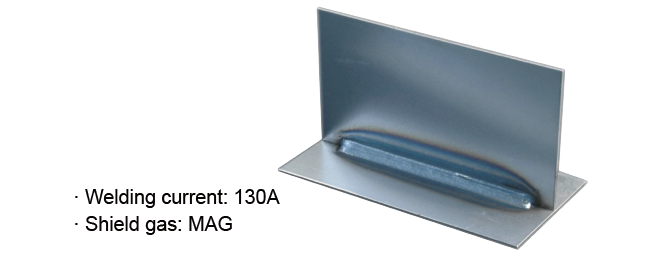

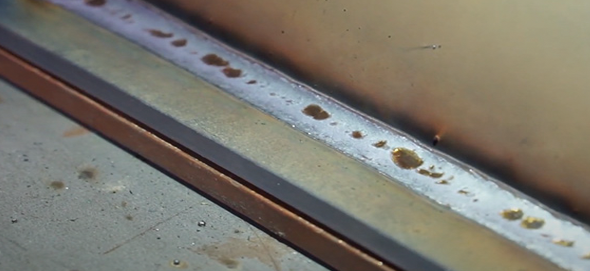

ULS (Ultra Low Spatters) - Stable and High Efficiency

The ULS process is a modified short-arc transfer arc with perfect waveform setting that greatly reduces spatter generation. In the pinch phrase, there is a special current interruption, the energy is extracted under the program setting, avoiding the explosion caused by the large current, and the surface tension of the molten pool warms the generated droplets. Even in CO2 and MAG welding, it can minimize the spatters, which means less rework, fewer rejects, less cleaning required and savings on wearing parts.