SubArc-1000XD/1250XD

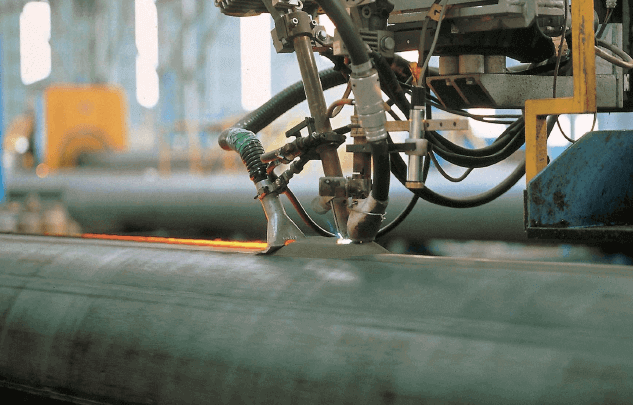

Increase Productivity, Quality and Flexibility

Processes:

Submerged Arc,

MIG,

Flux-Cored,

Gouging

Input Power:

340-460V/3-PH/50-60Hz

Rated Output at 40℃ (104℉):

SubArc-1000XD: 1000A/50V/100%

SubArc-1250XD: 1250A/50V/100%

Special features

TOP Features

- Ability to preset the current;

- 100% duty cycle with a maximum output capacity;

- Reduced heat affected zone, minimized distortion and increased mechanical properties;

- Overloading, over current, loss of phase and short circuit protection ensure long-lasting performance;

- Use the mode switch to select the desired output characteristics for the process being used–CC and CV;

- Versatile power source is capable to MMA, MIG/MAG and Carbon Arc Gouging;

- Precise output control results in a stable arc;

- Modular parallel to enhance reliability;

- User-friendly operation panel.

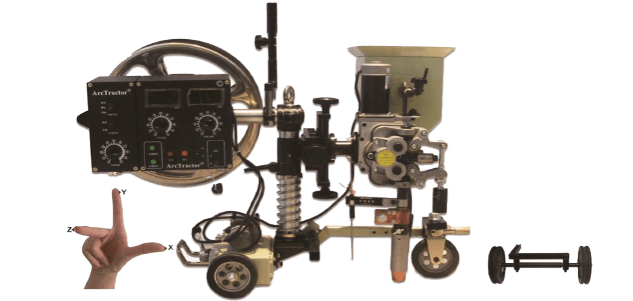

AT-1 SubArc Tractor

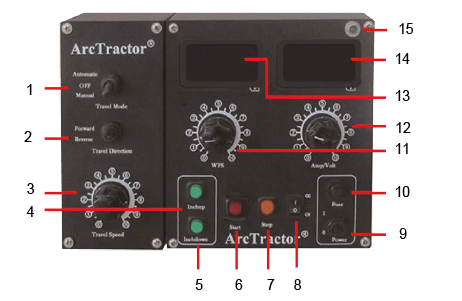

ArcTractor Controller

1.Auto/OFF/Manual Travel Switch

2.Travel direction- Forward/

Backward

3.Travel Speed Adjustment

4.Inch Up Button

5.Inch Down Button

6.Start Button

7.Stop Button

8. CC/CV Switch

9.Power Switch1

10.Circuit Breaker

11.Wire Feed Speed

12.Current/Voltage

Adjustment

13.Amps Display

14.Voltage Display

15.Power Indicator Light

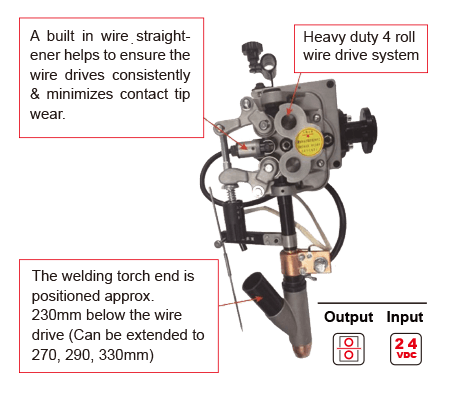

AH-1 SubArc Welding Head

- The pre-selection of nominal values for welding current, arc voltage and speed in coordination with the SubArc-1000XD /1250XD power source ensures a high degree of automation;

- The AH-1 welding head has an automatic ignition and automatic burn-back with withdraw for an optimized welding process;

- The welding head also has adjustment to angle forward or backwards by up to 45 degrees & side to side by up to 45 degrees;

- All welding heads are equipped with a laser pointer and a mechanical pointer for visual seam tracking. Via a cross support, the AH-1 can be manually positioned with an effective adjusting range of 100mm each;

LET'S STAY IN TOUCH

Get updates on sales specials and more

FOLLOW US

We want to hear from you!

Copyright © 2022 HANGZHOU TOPWELL TECHNOLOGY CO.,LTD. | 浙ICP备2022006748号