MIG-350HD

Synergic, MIG Welder

Application:

Metal fabrication workshops

Shipyards and offshore industry

Chemical and process industry

Steel structure workshops

Processes:

MIG

MAG

Flux-Cored

MMA(Stick)

Input Power:

400V, 3-Phase

Amperage Range:10-350A

Rated Output at 40℃ (104℉):

350A at 31.5V @60% Duty Cycle

Weight: 85KG

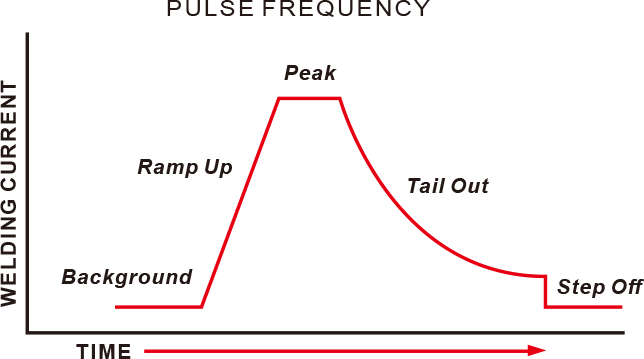

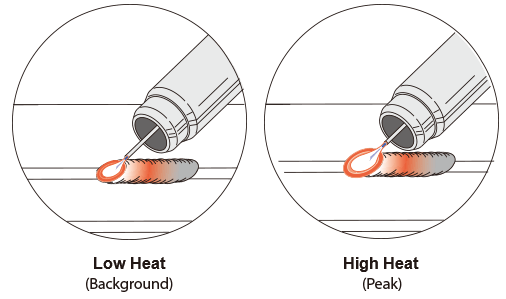

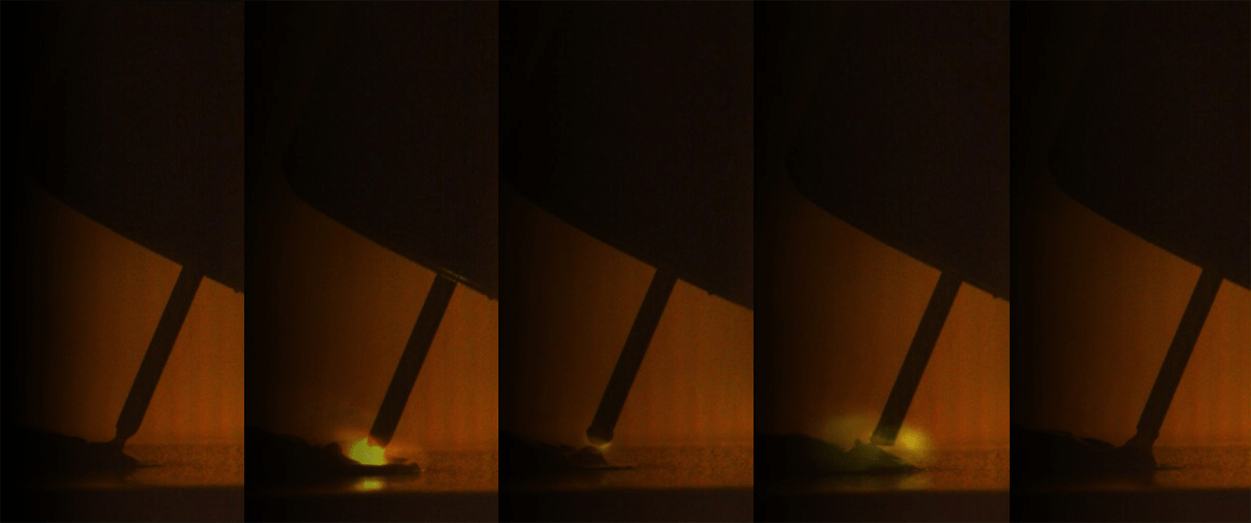

Pulse MIG

Pulsed MIG varies weld current between peak (high heat) and background (lowheat) current to provide better control of heat input, which minimizes warping and burnthrough on thin materials. Pulsed MIG also enables flat,horizontal, verticalup, or overhead welding without a slag system.Optimized GMAW-P waveforms are readily available to use on aluminum,carbon steel,high strength low alloy steel, stainless steel,and nickel alloys.

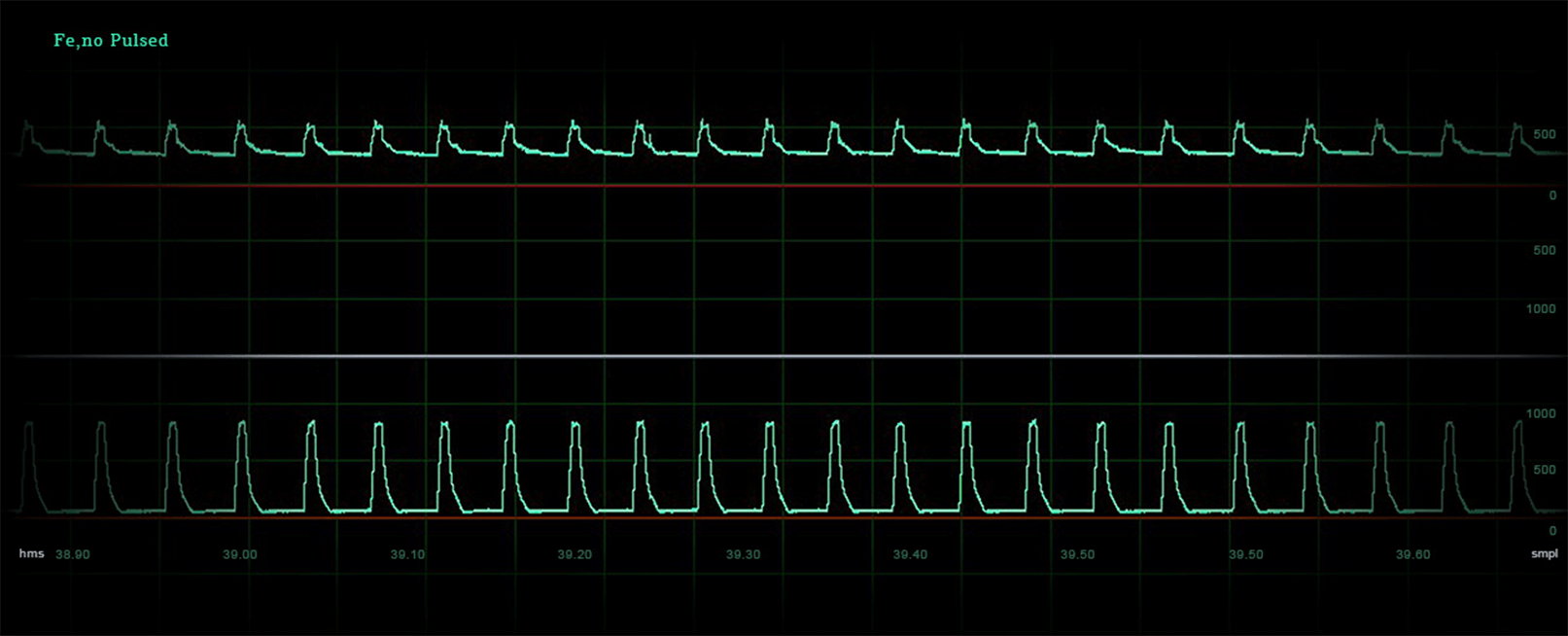

The advantage of Wave-form Control System

The latest technology of Waveform Control System, can perfectly control the output of welding power and get the precision Arc performance. The wire melting droplet transfer cycle is very clear, the welding beam is very clean and very few spatters during welding.

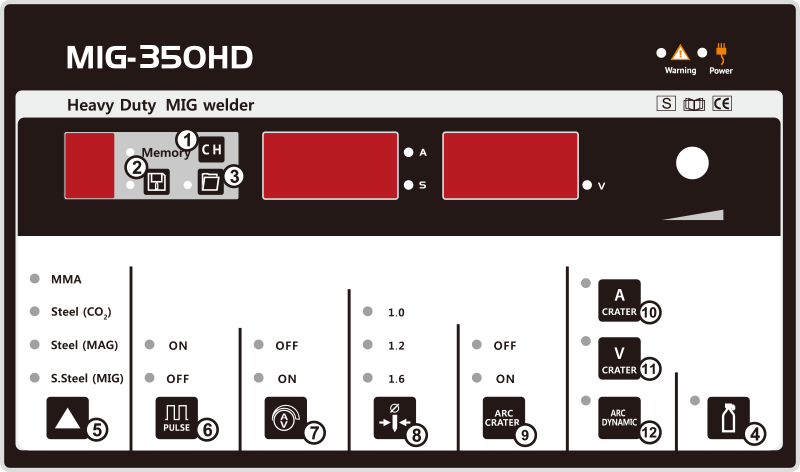

General View Of Control Panel

1.SELECT the Memory channel

2.OPEN the parameter of selected memory channel

3.STORE the setting to Memory channel

4.Push to Check Gas

5.Welding Process

MMA,

MAG(CO2)for Carbon steels

MAG(CO2 /Ar) for Carbon steels

MIG (Argon) for Stainless steels

6.Pulse MIG: ON/OFF

7.Synergic function ON/OFF

8.Synergic setting (select wire diameter)

9.Arc Crater: ON/OFF

10.Select to adjust the Arc Crater Current

11.Select to adjust the Arc Crater Voltage

12.Arc Dynamic controls

Classical MIG/MAG

TIn classic mode, MIG / MAG welding is carried out in inert gas with automatic wire feed.With this mode, a high welding speed and excellent quality are offered without any extra costs in the processing of ferrous metals, as well as various steels.

Synergic control

LET'S STAY IN TOUCH

Get updates on sales specials and more

FOLLOW US

We want to hear from you!

Copyright © 2010 - 2017 www.cn-topwell. All Rights Reserved