PowerCUT-70H

Professional-grade power plasma for cutting 12mm thickness metal @500mm/min

Application:

Home workshop

Metal workshops

Light fabrication,

Repair and maintenance

These Materials:

Mild Steel

Brass

Copper

Aluminum

Input Power:

340V-460V ,3-Phase:

Amperage Range: 30-70A

Rated Output at 40℃ (104℉):

70A at 125V @60% Duty Cycle

Weight: 22KG

Advantages

Maximum productivity

• Cutting 12mm @500mm/min ensures the maximum productivity (optional torch).

• Finish jobs much faster with cut speeds greater than oxyfuel.

Easy-to-use with versatile design

• Very easy to use, even for first time operators..

• Non-HF type available: Starts without high-frequency so it will not have electromagnetic interfere.

•Tackle different jobs with multiple, easy-to-use torches..

Low operating cost

• Reduce costs with long consumable life and more uptime.

• High power efficiency lowers energy consumption..

Rugged and reliable

• TOPWELL Certified reliability ensures performance in the most demanding environment..

• Powercool design cools internal components more effectively for long system life and improved uptime.

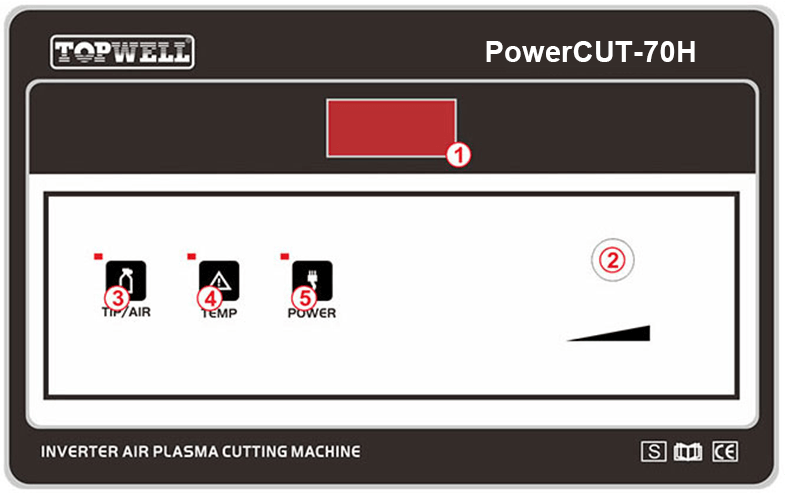

General View Of Control Panel

1.Ammeter/Voltmeter Display

2.Encoder Control

3.Gas supply problem

4.Over heat/Over loading

5.Power LED

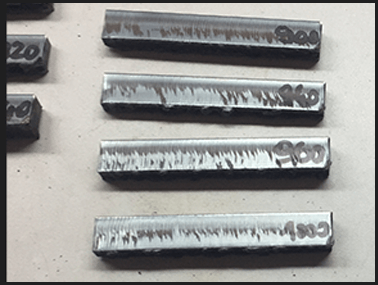

Cutting Capacity

| Capacity | Thickness | Cut speed |

|---|---|---|

| Recommended cut(Hand cutting) | 16mm | 500mm/min |

| Severance(hand cutting) | 25mm | 125mm/min |

| Pierce* | 12mm (Use TP-80Torch) |

| *Pierce rating for handheld use or with automatic torch height control |

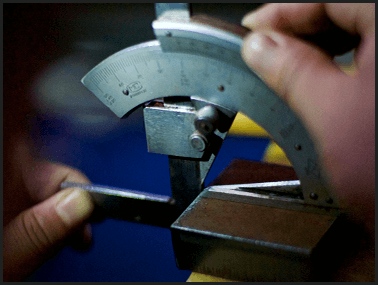

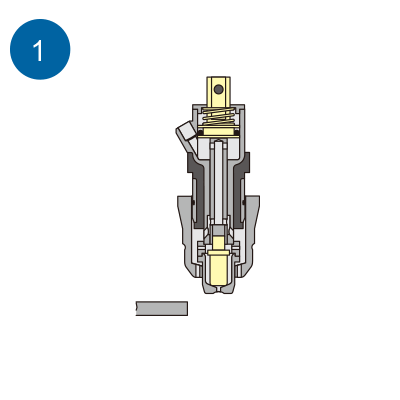

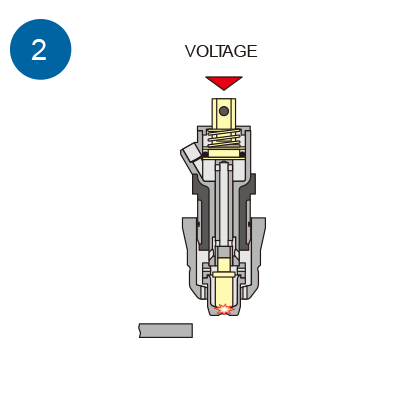

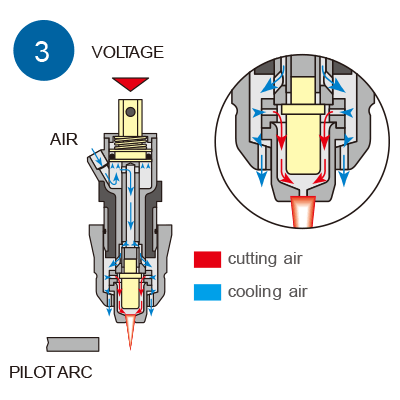

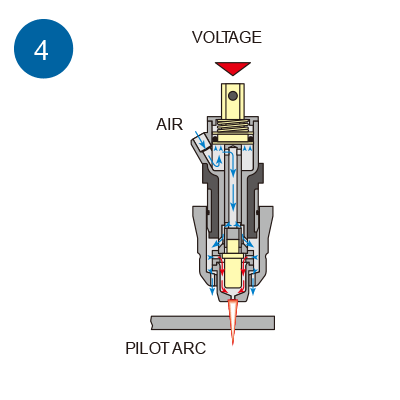

Non-HF Arc Ignition System

Torch off.

By pressing the trigger the torch will be fed by the current thus causing a temporary short circuit betweenelectrode and tip.

The air then pushes up the small piston, thuscreating, between the electrode and the tip, the distance needed to strike the pilot arc

By positioning the torch on the part to be cut, theplasma arc will strike..

Torches with pilot arc cut in without high frequency.

Less electromagnetic disturbance, with consequent absence of problems for any electronic, radio, television, telephone and computer systems in the vicinity of the cutting positions. Less electric stress on the torch - and on the respective connecting cables - due to the absence of the high voltage necessary for striking the arc Greater simplicity in comparson with other torches(without high frequency) on the market,with a consequent decrease of the risks of jamming in the mechanical pneumatic movement for striking the arc. Subject to wear (electrode, tips, nozzles, diffusers etc.), thanks to the better cooling of the torch obtained by reducing the insulating thicknesses (without endangering the safety parameters).

LET'S STAY IN TOUCH

Get updates on sales specials and more

FOLLOW US

We want to hear from you!

Copyright © 2010 - 2017 www.cn-topwell. All Rights Reserved